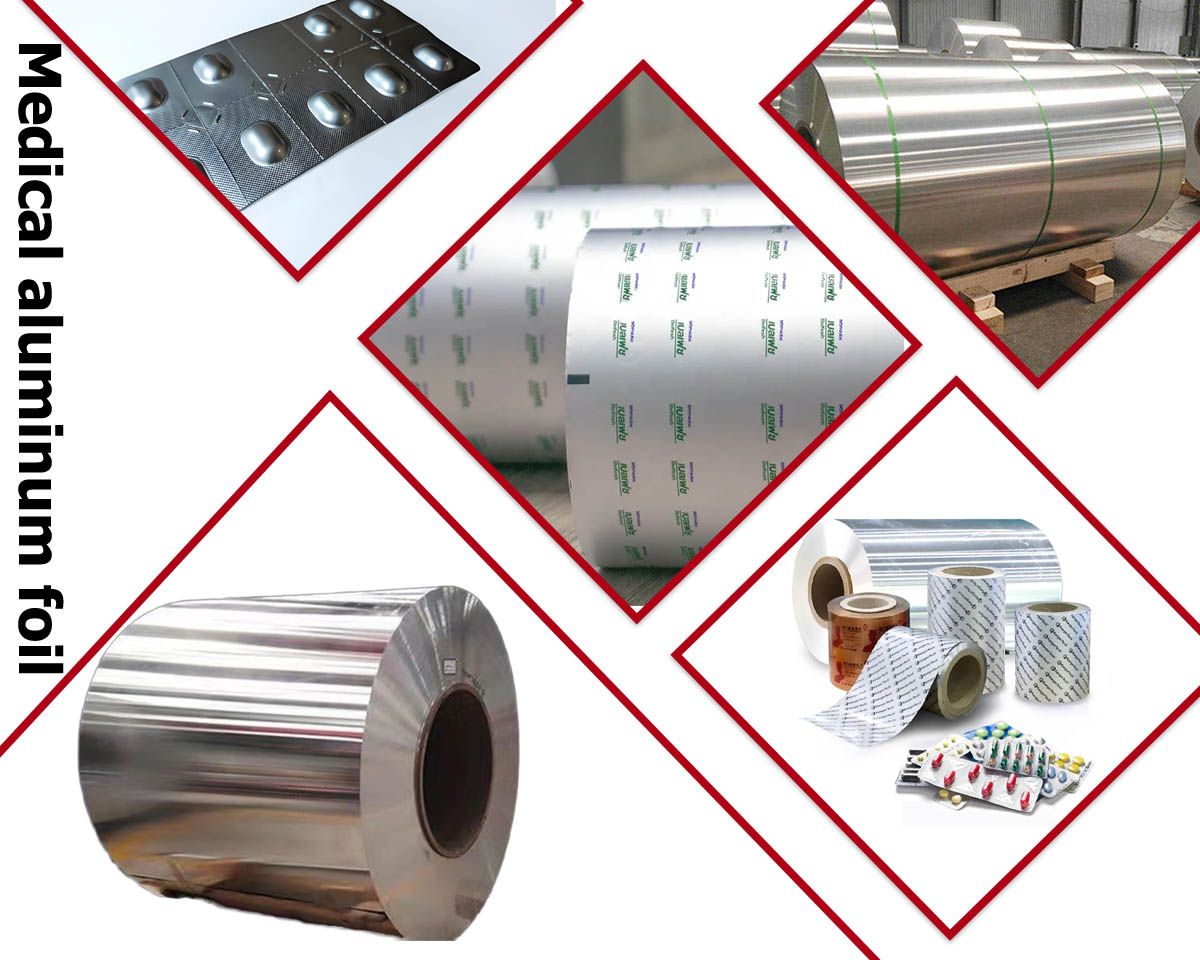

In modern pharmaceutical manufacturing, packaging is not only related to product appearance but directly affects drug safety, stability, and shelf life. Among various packaging materials, aluminum foil has become an indispensable core material in pharmaceutical packaging due to its excellent barrier properties, good processing adaptability, and a mature industrial supply chain.

This article provides a detailed overview of the main types of aluminum foil used in pharmaceutical packaging and the specific applications for each.

Why Is Aluminum Foil Essential in Pharmaceutical Packaging?

Pharmaceutical products place extremely strict requirements on packaging materials, which typically must offer:

High barrier performance: Effective protection against moisture, oxygen, light, and microorganisms

Chemical stability: No reaction with the drug product

Good forming and heat-sealing properties

Compliance with pharmaceutical packaging regulations and pharmacopeia standards

Aluminum foil excels in all these aspects and is especially suitable for tablets, capsules, powders, liquid formulations, and sterile pharmaceutical products.

Common Types of Pharmaceutical Aluminum Foil Products

1. PTP Pharmaceutical Aluminum Foil (Blister Foil)

PTP (Press Through Packaging) aluminum foil is the most familiar pharmaceutical foil in everyday life. When you press a tablet out of a blister pack with your finger, the punctured aluminum layer is PTP foil.

Its standard structure typically consists of a protective layer (OP), aluminum foil base (AL), and heat-seal coating (VC) for example, OP/AL/VC. Thickness generally ranges from 0.016 to 0.04 mm, using aluminum alloys such as 8011 or 8021.

PTP aluminum foil provides excellent oxygen barrier, light protection, and moisture resistance, and can be heat-sealed with PVC, PVDC, and other plastic blister films, ensuring drug stability throughout the shelf life. It is widely used for tablet and capsule blister packaging.

2. Cold Forming Aluminum Foil (ALU-ALU)

Cold forming aluminum, also known as Alu-Alu blister packaging material, is a three-layer laminated structure used for pharmaceuticals requiring extremely high moisture and oxygen protection.

A typical structure is BOPA (nylon) / aluminum foil / PVC. Unlike PTP foil, which relies on thermoforming, cold forming aluminum uses mechanical force to stamp the blister cavities.

The aluminum foil core is usually 8021-O or 8079-O, with a thickness of approximately 0.04-0.065 mm.

Due to higher iron content, 8021 and 8079 alloys offer excellent ductility and high cupping values, preventing cracking or pinholes during deep drawing. This creates a near-perfect "metal can" effect, effectively providing armor-like protection for sensitive drugs.

3. Tropical Blister Aluminum Foil

Tropical blister foil is designed specifically to ensure drug stability in hot and high-humidity climates.

This structure is often referred to as "Aluminum-Plastic-Aluminum" or a double-aluminum structure. In addition to the thermoformed plastic blister and standard lidding foil, an extra layer of cold-formed aluminum foil is added externally.

The dual aluminum layers work together to maintain package integrity even under extreme vapor pressure conditions. Common aluminum alloys include 8021-O and 8079-O, with thicknesses ranging from 0.016 to 0.2 mm.

Tropical blister packaging represents one of the most technically advanced and highest-cost solutions in pharmaceutical aluminum foil applications.

4. Aluminum Foil Sealing Lids and Liners

These products are mainly used for sealing bottled pharmaceuticals. An aluminum foil liner is placed inside the bottle cap and sealed using electromagnetic induction sealing equipment to ensure sterility and tamper evidence.

For this mechanical sealing application, 8011-H14 or H16 semi-hard aluminum foil is commonly used, with thicknesses ranging from 0.016 to 0.2 mm. This ensures the foil does not crack during sealing while maintaining sufficient resilience for tight closure.

5. Aluminum-Plastic Composite Pouches

Although aluminum-plastic composite pouches are a broader category, pure aluminum laminate pouches (e.g., PET/AL/PE) and metallized film laminates (e.g., VMPET/PE) are widely used in pharmaceutical packaging.

They are especially suitable for applications requiring high barrier properties, moisture resistance, and light protection.

Pharmaceutical Packaging Types and Their Applications

| Packaging Type | Application | Material Examples | Key Functions |

| Blister packaging | Tablets, capsules | PVC, PA, PET | Thermoforming, moisture & oxygen barrier |

| Sachets / stick packs | Powders, granules | Coated paper, aluminum, PE | Fully sealed, light- and gas-proof |

| Bottles | Drops, solutions | Amber glass, opaque plastic | Basic protection, stability |

| Ampoules / vials | Injectables | Clear glass, plastic | Shatter-resistant, sterilizable |

| Tubes | Creams, pastes, gels, ointments | Laminated films, aluminum foil | Prevent contamination, barrier protection |

| Four-side seal pouches | Medical supplies | Coated paper, PA films | Sterilizable, chemical & heat resistance |