In the pharmaceutical packaging industry, blister packaging is widely used for its excellent sealing properties, convenience, and safety. Within the blister packaging system, blister packaging aluminum foil serves as a key sealing material, directly affecting product protection, user experience, and regulatory compliance. This article provides an in-depth overview of blister foil and its significance in modern packaging solutions.

What is Blister Packaging Aluminum Foil?

Blister packaging aluminum foil, commonly referred to as PTP aluminum foil, is used as the push-through sealing material for the back of blister cavities. Typically made from hard-temper aluminum, it is coated with protective and heat-sealable layers through precise coating technologies. The foil acts as a container lid and serves as the first line of defense against external environmental factors. Consumers can easily press and push a tablet through the foil, ensuring convenient, hygienic, and safe product retrieval.

Types of Blister Foil

Depending on manufacturing process and application requirements, blister packaging aluminum foil is mainly categorized as follows:

| Type | Thickness (mm) | Temper / Hardness | Main Use | Key Feature | Typical Applications |

| Ultra-thin blister foil | 0.006 - 0.007 | Soft | Light push-through blister | Highly flexible, easy push, low force required | Medications for elderly, child-friendly drugs |

| Light blister aluminum foil | 0.008 - 0.012 | Soft | Standard blister sealing | Balanced flexibility and strength, good barrier performance | Conventional tablets, capsules |

| Strip packaging foil | 0.02 - 0.05 | Soft | Strip packaging | Double-aluminum structure, excellent barrier | High-safety medications, unit-dose packaging |

| Lidding foil | 0.012 - 0.025 | Soft–medium | Blister closure material | Adequate strength, can be pushed or peeled | Pharmaceuticals, dietary supplements |

| Cold forming foil | 0.045 - 0.06 | Soft | Cold-formed blister trays | Highest level of moisture, oxygen, and light protection | Highly sensitive or easily degraded drugs |

Key Characteristics of Blister Foil

1.Exceptional Barrier Properties: Aluminum foil nearly 100% blocks oxygen, moisture, UV light, and microbes-essential for oxidation-prone or hygroscopic drugs.

2.Push-Through Convenience: The foil has controlled brittleness, allowing consumers to easily press out tablets, leaving smooth edges.

3.Outstanding Stability: Performs reliably under extreme temperatures, non-toxic, tasteless, and compliant with strict food and pharmaceutical safety standards.

4.Security & Aesthetics: Metallic sheen and printable surface support brand identity and anti-counterfeiting measures.

5.Reliable Heat-Sealing: Heat-sealable coatings ensure stable sealing with blister cavities, reducing leakage risks.

6.Regulatory Compliance: High-quality blister foil meets USP, EP, JP, and other international regulations for food-contact and pharmaceutical materials.

Common Applications

Pharmaceuticals: For tablets, capsules, lozenges, and unit-dose packaging, ensuring product safety and traceability.

Dietary Supplements: Suitable for vitamins and functional supplements, enhancing consumer trust and product appeal.

Selected Food Products: For gum, functional candies, or other products requiring moisture protection and hygiene.

How to Select the Right Blister Foil

1. Product Sensitivity and Barrier Requirements

The primary function of aluminum foil is barrier protection. Select the appropriate foil according to your product’s environmental sensitivity:

Barrier Matching: For standard tablets and capsules, conventional PTP foil is sufficient. For highly sensitive products such as hormones, biologics, antitumor drugs, or light/moisture-sensitive formulations, cold-formed Alu-Alu foil is recommended for near-zero permeability to light, oxygen, and water vapor.

Shelf-Life Consideration: For long-term storage (12+ months), high-barrier foil (cold-forming) is preferred. For short-term storage, standard PTP foil is adequate.

2. Opening Mechanism (Based on Use Scenario)

Choose an opening type to balance usability and safety:

Push-Through: Ideal for standard tablets and capsules, using PTP foil with moderate flexibility for easy pressing while avoiding accidental breakage.

Peelable: Designed for quick, effortless access without resealing, often a composite of paper/PET/aluminum/HSC, suitable for disposable medical supplies or small supplements.

Peel-and-Push Hybrid: Combines push-through and peelable features for additional protection, often used for child-resistant pharmaceutical packaging.

3. Thickness and Temper

Foil thickness and temper determine strength, flexibility, and user feel:

Thickness:

Ultra-thin (0.006-0.007 mm) for lightweight products, highly flexible.

Thin (0.008-0.012 mm) for small devices or consumables.

Lidding foil (0.012-0.025 mm) for standard PTP applications.

Strip foil (0.02-0.05 mm) for unit-dose strip packaging.

Cold-forming foil (0.045-0.06 mm) for Alu-Alu blister trays with maximum protection.

Temper:

Soft (O temper) for high flexibility and ease of pressing, typical for medical and food-grade foils.

Hard temper for higher strength and wear resistance, suitable for industrial or rarely opened packages.

4. Special Requirements: Child-Resistance

For products that may be accessed by children, choose foils and blister designs compliant with child-safety regulations. Common solutions include hard or peel-and-push PTP structures, making opening difficult for children while allowing adult access.

5. Customization

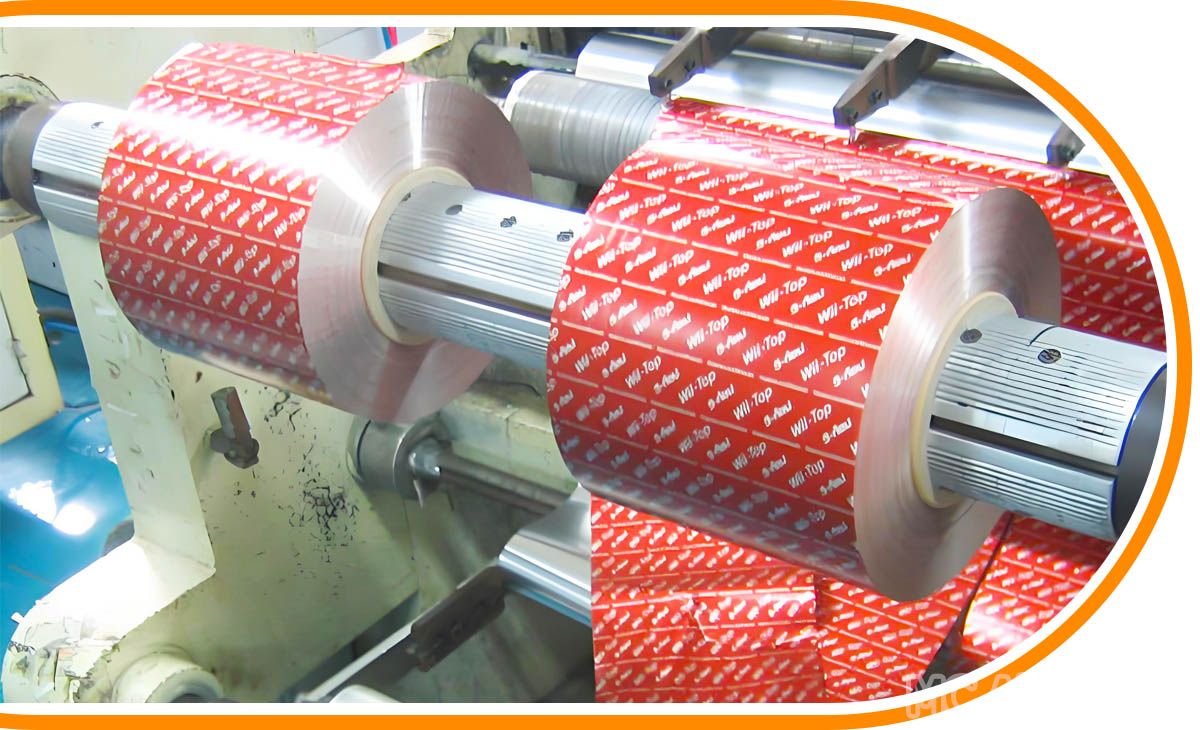

Printing: For branding, product information, batch codes, and anti-counterfeiting marks, choose foils with coatings suitable for high-quality printing.

Size & Shape: Ensure foil can be customized to match product dimensions and blister molds to optimize sealing efficiency and reduce material waste.

6. Cost Considerations

Balance cost with protection and functionality:

Standard PTP foil is cost-effective for conventional products.

Cold-forming foil is more expensive but provides superior protection for sensitive or high-value drugs.

Customization (printing, special opening mechanisms) adds cost and should align with brand and market strategy.

Summary: Selecting blister packaging aluminum foil should follow the principle: match product protection needs, adapt to user scenarios, and balance cost and customization, ensuring full product protection while providing convenience and economic efficiency.