- Xin'an Industrial, Luoyang,Henan Province,China

- sales@alummc.com

Products

1050 Aluminum Foil

The aluminum element content of 1050 aluminum foil is 99.5%. Since no other chemical elements need to be added, the production process of 1050 aluminum foil is simple, and the price is relatively cheap compared with alloy aluminum foil. It is a very widely used aluminum foil.

1060 Aluminium Foil

The aluminum content of 1060 aluminum foil is as high as 99.6%, which is a widely used industrial pure aluminum foil.1060 aluminum foil has excellent corrosion resistance, thermal conductivity and good processing performance, thus becoming an excellent raw material for aluminum foil gasket

Medicinal aluminum foil

Aluminum foil packaging has good shading, moisture resistance, compactness, can protect the inner packaged drugs from oxidation, moisture absorption and deterioration, good calendering, easy production, and easy disassembly. After compounding, printing and gluing, it is widely used in the packagi

5052 Aluminum Foil

5052 aluminum foil belongs to the aluminum-magnesium container foil alloy series. 5052 aluminum foil has the characteristics of moderate strength, good formability, corrosion resistance and good surface treatment effect. 5052 aluminum foil is a typical food-grade aluminum foil used for food packa

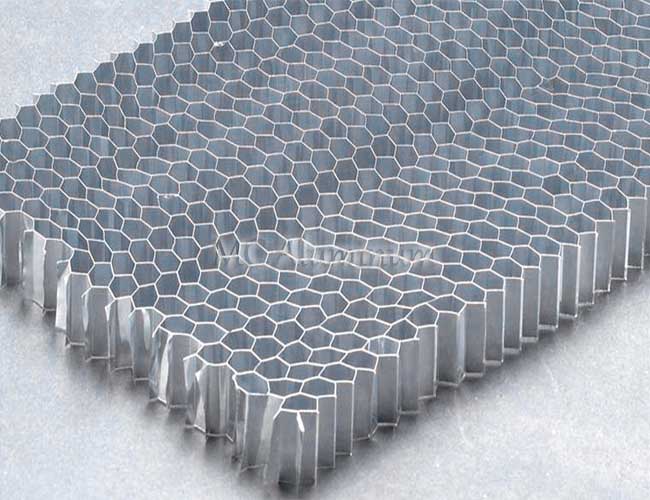

Honeycomb aluminum foil

The aluminum honeycomb core is bonded by multiple layers of aluminum foil, laminated, and then stretched and unfolded into a regular regular hexagonal honeycomb core. The aluminum honeycomb core has sharp, clear cell walls, no burrs, and is suitable for high-quality core-to-face bonding and other

Container foil

The thickness of the aluminum foil lunch box is generally between 0.03mm and 0.20mm, which can be divided into two types: wrinkled and wrinkle-free. The raw material of the lunch box is made of 3-series or 8-series aluminum foil, which is made by the production process of one-time automatic cold

8021 Aluminum Foil

MC Aluminum specializes in producing 8021 aluminum foil with a thickness range of 0.006mm-0.2mm and a width of 100-1600mm according to customer requirements. The commonly used tempering states of 8021 aluminum foil are H14, H18, H22 and H24. 821 aluminum foil is used in food packaging, batteries

8079 Aluminum Foil

8079 aluminum foil belongs to the 8××× series, which has high strength, good elongation and tensile properties. Compared with other alloy aluminum foils, 8079 aluminum foil has the advantages of moisture resistance, good air tightness, and good taste. It has a beautiful silver luster and is go

Cigarette Packaging Aluminum Foil

Tobacco is a perishable and often expensive consumer product that requires packaging to deliver it to consumers in optimal condition. Due to its light weight, good coating, non-toxic, moisture-proof, shading, thermal conductivity, high electrical conductivity, good corrosion resistance and beauti