- Xin'an Industrial, Luoyang,Henan Province,China

- sales@alummc.com

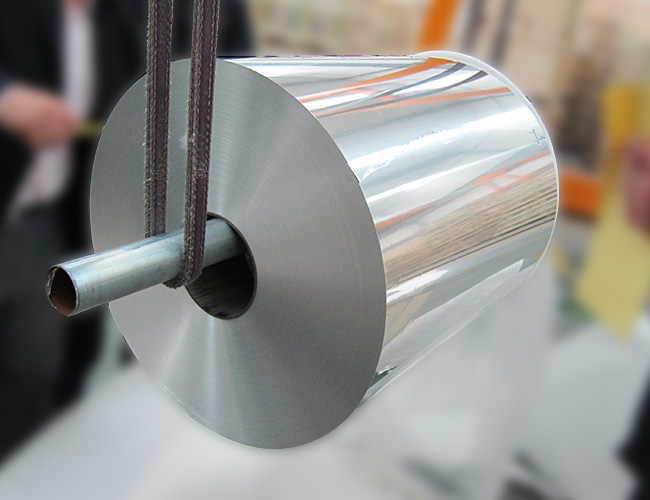

Container foil

Alloy:3003,8011

Thickness:0.02~0.055mm

Width:100~1600mm

Application:Aluminium foil containers and airline lunch boxes

The thickness of the aluminum foil lunch box is generally between 0.03mm and 0.20mm, which can be divided into two types: wrinkled and wrinkle-free. The raw material of the lunch box is made of 3-series or 8-series aluminum foil, which is made by the production process of one-time automatic cold stamping and forming with special equipment and molds. The aluminum foil lunch box is environmentally friendly, hygienic, and easy to recycle, and meets the national food hygiene standards.

The 8011 aluminum foil and 3003 aluminum foil substrates produced by MC Aluminium are the source of aluminum foil raw materials for various aluminum foil container factories at home and abroad.

Container foil Advantage:

1. Safety and hygiene, green environmental protection, renewable energy saving

2. Good sealing, no adsorption

3. High strength and deformation resistance, not easy to break

4. Can inhibit bacterial growth and can be cleaned with steam

Container foil Specification:

| Alloy | Temper | Thickness | Width | Length |

| 3003 | O、H22、H24 | 0.02~0.055mm | 100~1600mm | c |

| 8011 |

Application of Container foil:

For making various aluminum foil containers and airline lunch boxes.

Packing & Delivery:

PE foam is the first layer, plastic bag is the second layer, and then montmorillonite desiccant is put in to prevent corrosion. Wrapped in paper as a third layer, the roll is suspended in a nautical-friendly wooden box, and the edges of the roll are protected from mechanical damage with Styrofoam.

Contact Us

Address

- Xin'an Industrial, Luoyang,Henan Province,China

- sales@alummc.com alummc@hotmail.com