In the pharmaceutical industry, packaging is not just about appearance—it plays a vital role in protecting drug safety and therapeutic efficacy. Among various packaging solutions, blister packaging is the most common format, and its core material is blister aluminum foil. Few realize that the thickness of this seemingly thin layer of foil can directly influence a medicine’s shelf life, safety, and even the patient’s usage experience.

What is Blister Aluminum Foil?

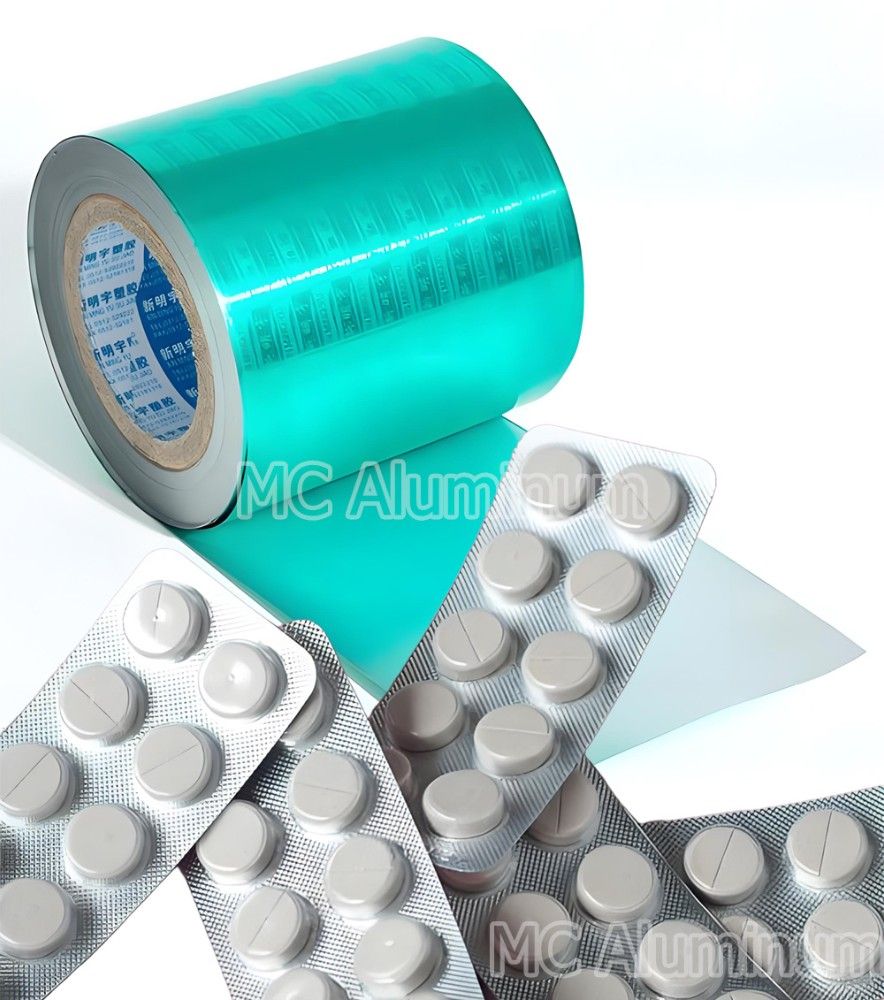

Blister aluminum foil is a specially designed composite material used in pharmaceutical blister packs. It is typically made from hard-tempered (H18) aluminum foil (such as alloys 8011, 8021, or 8079), laminated with plastic films like PVC, PVDC, or PP. Through heat-sealing, tablets and capsules are individually sealed in protective “blisters.”

Blister foil provides excellent barriers against moisture, oxygen, light, and microorganisms, while also offering strong mechanical protection during transport and storage. This ensures that drugs remain stable and safe throughout their shelf life. For these reasons, blister aluminum foil is often referred to as “the last line of defense for drug safety.”

Interaction Between Thickness and Other Foil Properties

When evaluating blister foil thickness, it should not be considered in isolation. Its performance is closely tied to other material properties:

1. Temper

Hard temper (H18) is the standard for push-through blister lids due to its high hardness and brittleness. The foil thickness must be compatible with the temper to achieve the right balance between barrier protection and push-through performance. Too thin or incorrectly tempered foil may tear or deform excessively.

2. Alloy Type

8011: Good formability and strength, widely used in standard blister packaging.

8021: Excellent elongation and formability, ideal for complex blister shapes or applications requiring higher puncture resistance.

8079: Combines high strength with superior ductility, offering a balance between lightweighting and durability.

Choosing the right alloy sometimes allows a reduction in thickness without sacrificing performance, which can also reduce material costs.

3. Coatings

While heat-seal lacquer (HSL) and primers contribute little to mechanical strength, they are essential for sealing integrity and printability. However, the aluminum substrate thickness remains the primary determinant of barrier properties and mechanical strength, with coatings playing only a supporting role.

Why Thickness is Crucial

Protective Performance:

The main function of blister foil is to block moisture, oxygen, light, and odors. If too thin, the foil’s barrier performance diminishes, risking drug degradation through moisture absorption, oxidation, or spoilage.Mechanical Strength:

Blister packs are formed by cold or thermoforming. The foil must have sufficient ductility and tear resistance. If too thin, it may rupture during forming or shipping; if too thick, it becomes harder to form and may even damage molds.Child Resistance:

For child-resistant blisters, thickness is a key factor. It must be thick enough to make accidental access difficult, but not so thick that adults or patients struggle to open it.Push-Through Functionality:

Patients must be able to easily push tablets or capsules through the foil. Thickness must strike a delicate balance—strong enough to protect the product, but thin enough for clean, controlled push-through without excessive force or fragmentation.Cost Efficiency:

Thicker foils are more robust but consume more material, increasing costs. Optimized thickness ensures performance without unnecessary expense.

Common Blister Aluminum Foil Thickness and Its Application

| Nominal Thickness | Typical Alloy | Common Applications | Key Considerations |

| 20 µm (0.020 mm) | 8011-H18, 8079-H18 | Standard tablets/capsules, less sensitive products | Good balance of barrier, push-through, and cost; most common for general pharma. |

| 22 µm (0.022 mm) | 8011-H18, 8021-H18 | Slightly more robust applications, improved handling | Enhanced puncture resistance over 20 µm. |

| 25 µm (0.025 mm) | 8011-H18, 8021-H18 | More sensitive drugs, demanding handling, CR applications | Superior barrier, increased strength, often used in CR/SF lidding structures. |

| 28 µm (0.028 mm) | 8021-H18, 8079-H18 | High sensitivity products, export markets with rough handling | Excellent mechanical strength and barrier; may require adjusted sealing parameters. |

| 30 µm (0.030 mm) | 8021-H18, 8079-H18 | Very demanding applications, special requirements | Maximum protection, sometimes used for larger or unusually shaped products. |

How Thickness Affects Key Performance Indicators

1. Water Vapor Transmission Rate (WVTR):

While aluminum is nearly impermeable, ultra-thin foils are prone to microscopic pinholes, allowing moisture ingress. Thicker foils significantly reduce pinhole risk, providing more reliable moisture protection. Standard pharmaceutical blister foils (e.g., 20µm) already achieve WVTR values close to zero.

2. Oxygen Transmission Rate (OTR):

Similar to moisture, aluminum’s intrinsic OTR is almost zero. Thickness ensures mechanical stability, preventing cracks or damage that could compromise oxygen protection.

3. Tensile Strength & Elongation:

Thicker foils generally offer higher tensile strength, improving resistance to tearing during manufacturing and use. Elongation is primarily alloy-dependent but also influenced by thickness.

4. Burst Strength:

Thicker foils withstand higher pressure before breaking, which is critical for protecting products during shipping and handling.

5. Seal Strength:

Although seal integrity mainly depends on HSL formulation and process parameters, foil thickness provides a stable substrate. Foils that are too thin may wrinkle or deform under sealing pressure, causing weak or inconsistent seals.

Why Choose Us?

Premium Raw Materials: High-purity aluminum, non-toxic, meeting pharmaceutical-grade standards.

Advanced Processing: State-of-the-art coating and rolling technologies, ensuring uniform thickness and superior sealing.

Customization Options: Wide range of thicknesses, specifications, and print designs tailored to your packaging needs.

Reliable Supply: Large-scale production capacity, strong inventory, and on-time delivery.

Certified Quality: ISO and GMP-certified, trusted by global pharmaceutical companies.