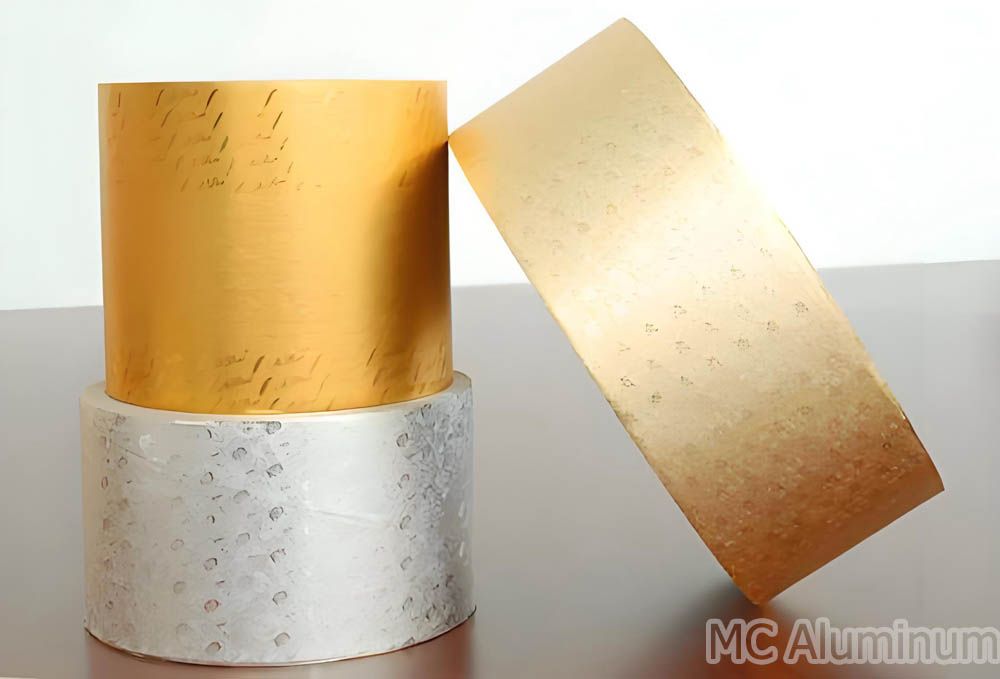

Tobacco inner liner aluminum foil often referred to as cigarette inner liner or inner foil not only provides a premium visual appeal to cigarette packaging but also plays a critical role in preserving the quality of the tobacco inside.

The thickness of cigarette inner liner foil is defined by strict industrial standards. Commonly known in the industry as "cigarette foil," it belongs to the category of double-zero foil, meaning its thickness is measured in the 0.0x mm range.

In actual production and supplier specifications, the most commonly used thickness for tobacco inner liner aluminum foil is 6.5 microns, with a typical tolerance of ±0.5 microns. Some high-quality manufacturers offer 0.006 mm (6 microns) foil while ensuring precise thickness uniformity.

In theory, thicker foil provides better barrier performance. However, excessive thickness increases hardness and brittleness, leading to cracks or creases during high-speed packaging ultimately affecting seal integrity. Therefore, engineers optimize alloy composition and rolling technology to strike the perfect balance. Common aluminum alloys used for cigarette foil include 8011, 1235, and 8006, known for maintaining excellent performance even at extremely thin gauges.

Advantages of 0.006 mm Cigarette Foil

1. Barrier Performance

Aluminum foil effectively blocks moisture, oxygen, and light, preventing tobacco from becoming damp, oxidized, or losing aroma.

2. Mechanical Workability

Tobacco inner liner foil requires good elongation (above 2%) and flexibility. It must withstand precise cutting, folding, and wrapping on high-speed packaging machines without tearing.

3. Cost Efficiency

Aluminum is one of the more expensive components in cigarette packaging. Reducing foil thickness by even 1 micron can significantly reduce raw material costs while maintaining performance.

4. Sustainability & Regulations

Global packaging standards increasingly emphasize environmental responsibility. Using thinner aluminum foil reduces material consumption and carbon footprint, aligning with sustainability trends in the tobacco industry.

Quality Requirements for Cigarette Inner Liner Aluminum Foil

1. Thickness Tolerance

Deviation must be tightly controlled, typically within ±5%.

2. Tensile Strength & Elongation

Foil must meet specific mechanical requirements to prevent breakage during high-speed unwinding and pulling. Adequate elongation ensures flexibility for smooth folding.

3. Pinholes (Pinhole Count)

Pinholes must be extremely minimal, verified using photoelectric inspection. High-grade foil limits pinholes per square meter to strict industry standards.

4. Flatness & Edge Quality

Foil rolls must have clean, smooth edges and tight, uniform end faces. Issues like "tower shape" or "cauliflower edges" must be strictly avoided.

5. Printing Compatibility

The foil surface must be smooth, free of oil stains, scratches, or oxidation marks to ensure high-resolution color printing and excellent color reproduction.

6. Gloss Level

Gloss must be consistent and customizable (high-gloss, matte, or ultra-matte). Matte foil must exhibit uniform gloss without shiny spots.

7. Odor Testing

The foil and all laminated layers, including inks and adhesives, must pass stringent odor tests to ensure no foreign smells affect tobacco flavor.