In the modern refrigeration and air conditioning industry, aluminum foil has become one of the core materials for heat exchangers. It is gradually replacing traditional copper due to its light weight, excellent thermal conductivity, corrosion resistance, and cost-effectiveness. As a green, lightweight, and energy-saving solution, aluminum foil is now the preferred choice for global air conditioner manufacturers.

MC Aluminum specializes in producing 8011, 1100, and 3102 alloy aluminum foils in H22 temper, with a thickness range of 0.07–0.2 mm. These foils are widely used in household air conditioners, central air conditioning systems, automotive AC, and industrial refrigeration equipment. They serve as the essential raw material for manufacturing fins in heat exchangers.

Why Choose H22 Temper?

Why Choose H22 Temper?

H22 is a common work-hardened temper that provides a balance between strength and formability. It is achieved through strain hardening followed by partial annealing. Its key features include:

Higher strength than O temper (annealed) :ensuring stable structures after forming.

Better ductility than H24/H26 tempers:suitable for deep drawing and bending.

Excellent processing adaptability:supports secondary processes such as stamping, coating, and brazing.

This makes H22 temper the ideal state for air conditioning fin stock, offering both good mechanical properties and corrosion resistance, while maintaining formability during production.

Air Conditioning Aluminum Foil Product Information

| Alloys | 8011, 1100, 3102 |

| Temper | H22 / H18 |

| Thickness | 0.07-0.2 mm (customizable) |

| Width | 100-1600 mm |

| Length | 100-6000 mm |

| Core ID | 76 mm, 152 mm, 200 mm (optional) |

| Common Dimensions | Fin stock: 0.07 / 0.08 * (16-28) mm Tubes: (0.27-0.32) * (35-75) mm Sheets: (0.6-1.5) * (659-1070) * (500-2500) mm |

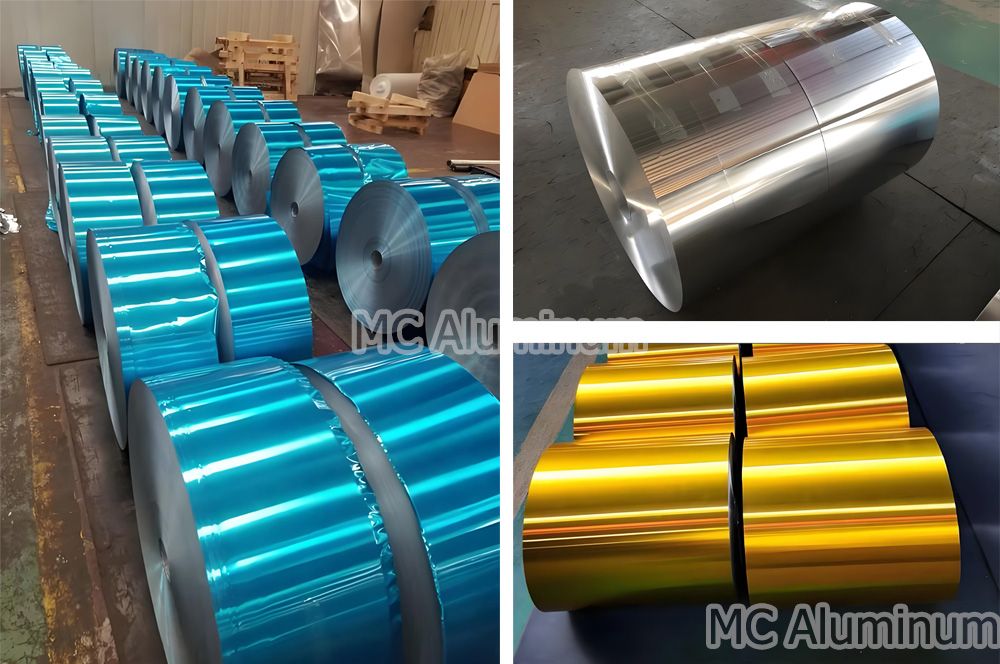

| Coating Colors | Gold, Blue |

| Surface Treatment | Hydrophilic, epoxy resin, etc. |

| Applications | Condensers, evaporators, oil coolers, heater cores, refrigerators, air conditioners, EV battery cooling systems,etc |

| MOQ | 1-3 tons |

Key Properties of Air Conditioning Foil

1. Excellent Formability:withstands multiple stamping and deformation processes without cracking.

2. High Thermal Conductivity:thin structure and excellent heat transfer for efficient cooling.

3. Superior Corrosion Resistance:resists moisture, salt spray, and chemical attack, extending service life.

4. Hydrophilic Coating (for hydrophilic foil): Promotes film-like water condensation instead of droplets, reducing air resistance and improving heat exchange efficiency.

5. Appropriate Strength: Maintains fin shape during manufacturing and operation.

6. Lightweight: Reduces overall equipment weight and improves energy efficiency ratio (EER).

Application Scenarios

Household Air Conditioners: Commonly used in evaporator and condenser fins.

Central Air Conditioning Systems: 1100 and 3102 alloy foils are widely applied in large-scale cooling systems due to their high conductivity and strength.

Automotive Air Conditioning: Growing demand for lightweight solutions makes 3102 industrial foil the mainstream choice.

Cold Chain & Industrial Refrigeration: Used in cold storage, refrigerated trucks, freezers, and other systems to optimize energy utilization.

Why Choose MC Aluminum's Air Conditioning Foil?

1. Premium Surface Quality: No pinholes, scratches, dents, oil stains, or dust; uniform thickness guaranteed.

2. High Strength & Durability: Excellent corrosion resistance against alkaline, salt spray, and humid environments.

3. Superior Hydrophilic Properties: Initial hydrophilicity a < 100; after environmental testing a < 250.

4. Strong Coating Adhesion: Uniform coating thickness, excellent durability, and long-term performance.