When you open a pack of cigarettes, the first thing you notice is the shiny metallic inner liner - the aluminum foil paper. Far beyond a decorative element, this thin layer of metal is a crucial barrier that preserves the quality of the cigarettes. Through excellent barrier performance and precise craftsmanship, it ensures that every cigarette reaches the consumer in optimal condition.

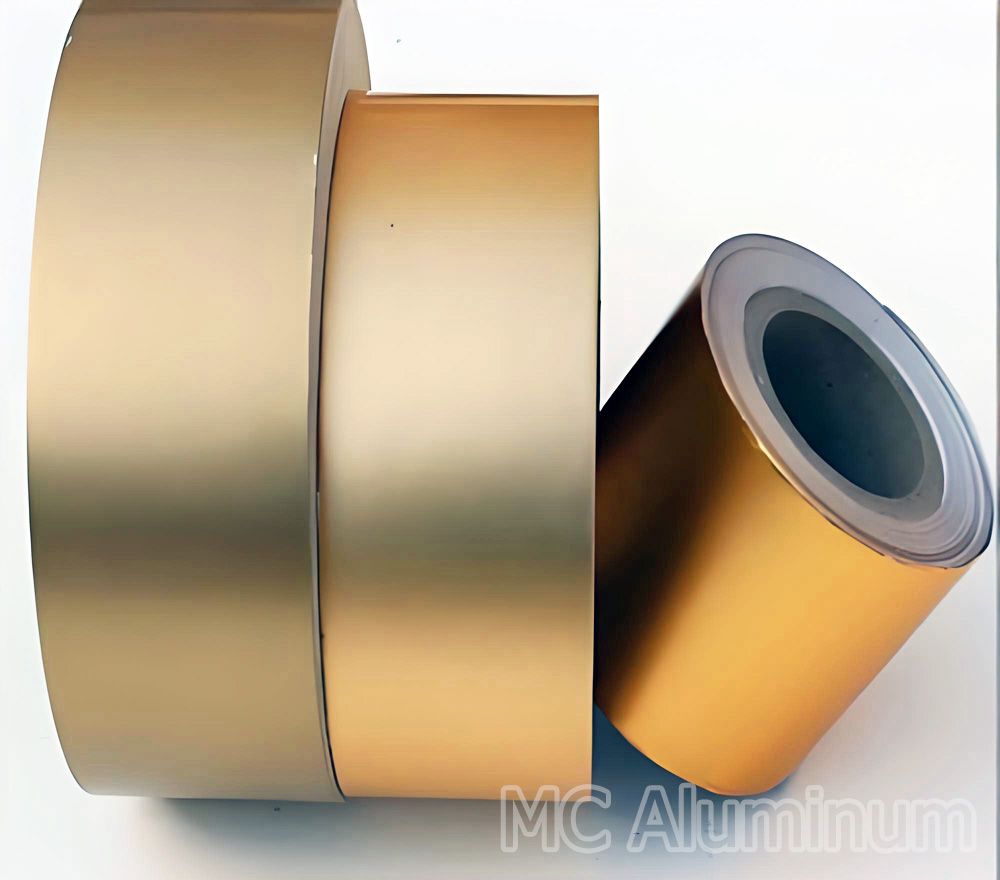

MC Aluminum supplies cigarette inner liner aluminum foil paper made from high-purity 1235 and 8079 aluminum foils, with thickness ranging from 0.010–0.025 mm. The material undergoes stretching, annealing, and coating processes to ensure excellent flexibility, printability, and barrier properties.

Structural Composition

1. Aluminum Foil Layer (Core Functional Layer)

Material: High-purity aluminum foil, typically alloy 1235 or 8079, with a thickness of 6.0μm-7.0μm.

Functional Characteristics:

High Barrier Property: Aluminum foil provides nearly perfect barrier protection against water vapor, oxygen, and light (zero permeability). This is its most critical function-preserving cigarette moisture and aroma while preventing oxidation and environmental damage to tobacco.

Thermal Reflectivity: Reflects heat to maintain a relatively constant temperature inside the package, slowing down the aging of tobacco.

2. Paper Layer (Base and Printing Layer)

Material: High-whiteness, high-tensile-strength thin paper, typically 20-30 g/m² wood pulp paper.

Functional Characteristics:

Structural Support: Provides necessary mechanical strength and stiffness for the soft aluminum foil, ensuring smooth operation on automated packaging machines.

Printing Base: Offers a printable surface for high-precision printing, allowing brand logos and design elements to be applied effectively.

3. Adhesive Layer

Functional Characteristics:

Used to bond the aluminum foil and paper layers securely. The adhesive must be environmentally friendly, non-toxic, and odor-free, ensuring that it does not affect the flavor or aroma of the tobacco.

Cigarette Foil Specifications

| Alloy | 1235, 8079 |

| Temper | O |

| Thickness | 0.006mm - 0.007mm |

| Width | 200 - 1450mm |

| Length | Customizable |

| Core ID | 76 / 152mm |

| Temperature Resistance | -20℃ to 150℃ (short-term high temperature allowed) |

| Surface Treatment | Bright, matte, embossed, coated, printed |

| Application | Cigarette packaging |

| Sample | Available |

| MOQ | 1-3 tons |

Mechanical Properties

| Tensile Strength | 80-90 MPa |

| Elongation | ≥1% |

| Pinholes | 0.006mm thick:≤500 holes/m² |

| 0.0063–0.0065mm thick: ≤300 holes/m² | |

| Surface Wetting Tension | A Grade |

Core Functional Advantages of Aluminum Foil Inner Liner

Aroma Preservation: Prevents aroma loss and blocks external odors, maintaining the original fragrance of the tobacco.

Mold Prevention: Blocks moisture to prevent mold growth and extend shelf life.

Light Shielding: The aluminum foil layer completely blocks UV and visible light, protecting light-sensitive components from degradation and ensuring product stability.

Anti-Wrinkle: The composite aluminum foil provides elastic support to reduce creasing and deformation during packaging.

Strict Quality Control for Cigarette Packaging Foil

1. Pinhole Control: Minimizes pinholes to enhance barrier performance; the latest standards have reduced pinhole count by 10-15%.

2. Bonding Strength: Ensures firm adhesion between layers with no delamination.

3. Surface Quality: Guarantees a smooth, clean, wrinkle-free, and contamination-free surface.

4. Hygiene & Safety: Meets food-grade packaging standards-non-toxic, odorless, and free from harmful migration or contamination.

FAQ

Q1: What is the typical thickness of cigarette aluminum foil paper?

A1: The standard thickness is 0.010-0.025 mm, and it can be customized based on cigarette pack size and packaging requirements.

Q2: How long can aluminum foil liners prevent moisture?

A2: In sealed cigarette packs, standard foil liners can keep cigarettes dry for over 6 months, while premium foil can extend protection to more than 1 year.

Q3: Is cigarette aluminum foil safe?

A3: Yes. It is made from food-grade high-purity aluminum, non-toxic and harmless, fully compliant with tobacco industry safety standards.

Q4: Can aluminum foil inner liners be printed?

A4: Absolutely. They support screen printing, flexographic printing, hot stamping, and coating, enhancing visual appeal and brand recognition.

Q5: Can aluminum foil be replaced by paper or plastic?

A5: Lower-end cigarettes may use paper or plastic liners, but their barrier and aroma-preserving properties are inferior. High-end cigarettes still require aluminum foil liners.

Q6: Is aluminum foil environmentally friendly?

A6: Yes. Aluminum foil is recyclable and eco-friendly, reducing packaging waste in the tobacco industry.