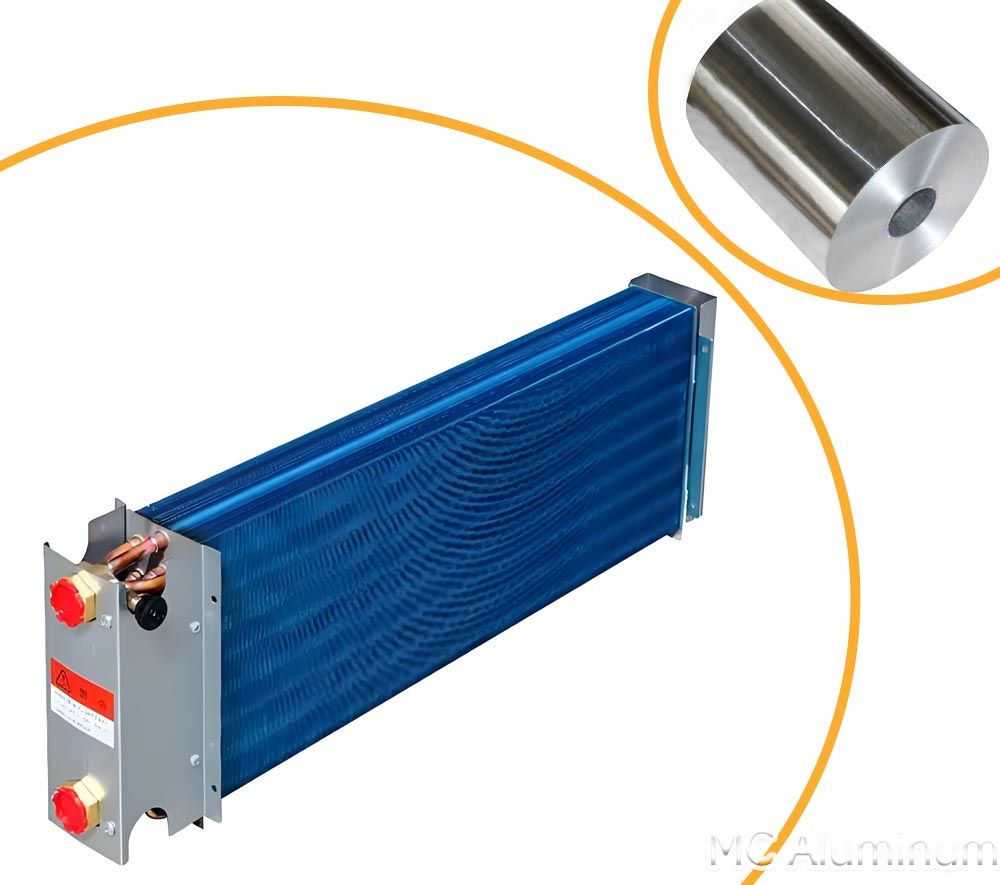

In modern refrigeration and heat exchange equipment, the performance of heat sink fins directly affects the overall energy efficiency of the system. As a core material for heat exchangers, hydrophilic aluminum foil has become the preferred choice for air conditioners, refrigerators, and automotive cooling systems due to its excellent wettability and corrosion resistance.

Hydrophilic aluminum foil for heat sink fins is typically produced using 8011, 3003, 3102, or 1100 aluminum alloys as the base material. A hydrophilic coating is applied to the aluminum foil surface through chemical or physical processes. This coating allows condensate water to spread quickly into a uniform water film on the fin surface rather than forming droplets, effectively improving airflow conditions and enhancing overall heat transfer efficiency.

Four Core Advantages of Hydrophilic Aluminum Foil in Heat Sink Fins

1. Improved Heat Transfer Efficiency

Under cooling or dehumidification conditions, conventional aluminum foil tends to form water droplets that obstruct airflow. Hydrophilic aluminum foil enables rapid drainage, reduces air resistance, and allows smoother airflow through the fins, significantly improving heat exchange performance.

2. Reduced Operating Noise

When condensate forms droplets and falls, it can generate operational noise. The hydrophilic coating promotes uniform water film distribution, effectively reducing noise levels during the operation of air conditioning and refrigeration equipment.

3. Excellent Corrosion Resistance

High-quality hydrophilic coatings typically offer strong resistance to salt spray, humid heat, and chemical corrosion, extending the service life of fins in humid environments. This makes them particularly suitable for coastal and high-humidity regions.

4. Good Formability and Processability

For the complex stamping processes used in fin production, premium hydrophilic aluminum foil provides excellent coating adhesion and ductility. During high-speed fin stamping, the coating remains intact without peeling, ensuring consistent appearance and performance of the final product.

Technical Parameters of Hydrophilic Coated Aluminum Foil

| Alloy | 8011 / 3003 / 3102 / 1100 |

| Temper | H22 / H24 |

| Thickness | 0.08 - 0.15 mm |

| Width | 100 - 1600 mm |

| Length | Customizable |

| Surface Treatment | Hydrophilic coating |

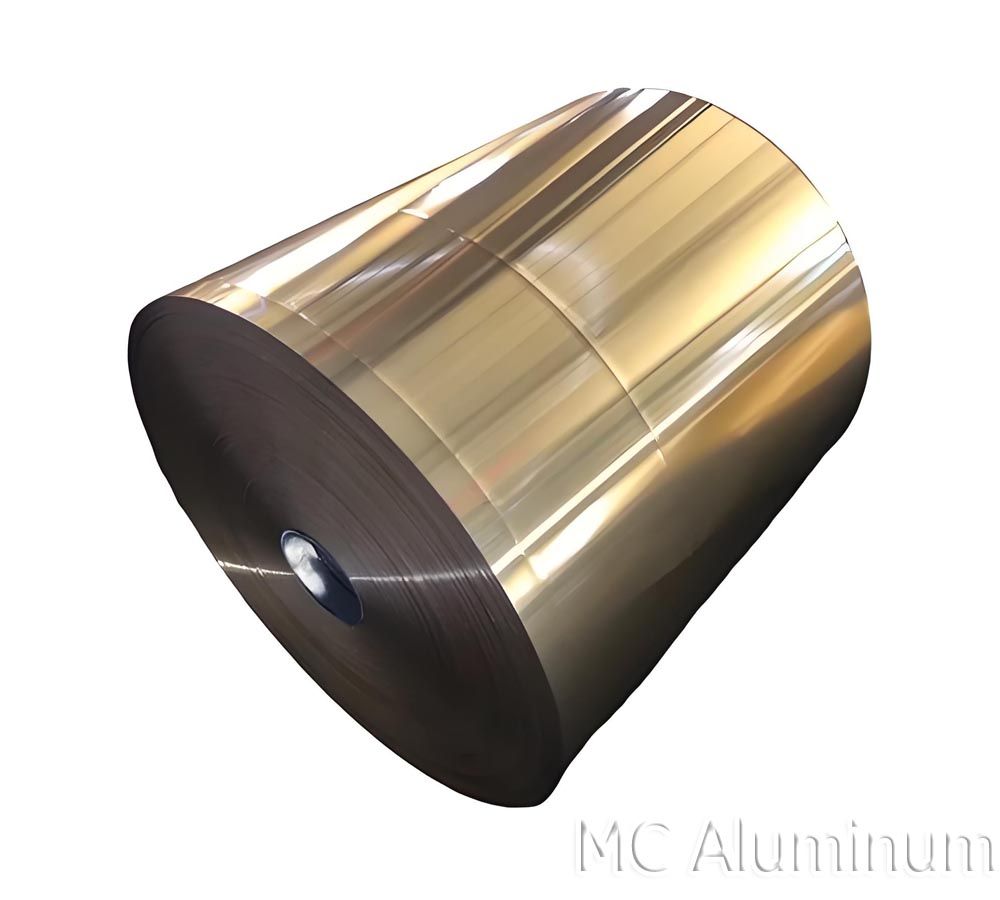

| Coating Colors | Blue, gold, black, green (customizable) |

| Applications | Air conditioner, condenser, evaporator fins |

| MOQ | 1-3 tons |

Manufacturing Process of Hydrophilic Aluminum Foil

Base Material Selection:

High-purity aluminum alloys (such as 1xxx and 3xxx series) are selected and processed through melting, casting, homogenization, and rolling to obtain foil stock with uniform microstructure and stable mechanical properties.

Precision Rolling:

Modern cold rolling mills are used to precisely control roll gap and tension, producing base foil with uniform thickness (typically 0.07–0.15 mm) and smooth surface finish.

Surface Pretreatment:

Strict degreasing and chemical cleaning processes are applied to ensure optimal surface cleanliness and activity, providing a solid foundation for strong coating adhesion.

Precision Coating:

As the core process, high-speed precision roller coating technology is used to evenly apply proprietary hydrophilic coating formulations onto the aluminum foil surface. Coating weight is accurately controlled to achieve optimal performance and cost efficiency.

High-Temperature Curing:

Under controlled temperature profiles, organic resins in the coating crosslink and cure, while inorganic hydrophilic components bond stably to form a durable and uniform functional film.

Strict Inspection and Slitting:

Key indicators such as contact angle, coating thickness, corrosion resistance, and adhesion are tested using specialized instruments. Qualified material is then slit and rewound according to customer specifications.

Application Areas of Hydrophilic Aluminum Foil

Refrigeration Equipment: Evaporators for refrigerators, freezers, and dehumidifiers

Electronic Thermal Management: Heat sink fins for high-power inverters, server cooling units, and photovoltaic inverters

New Energy Vehicles: Battery thermal management systems and air conditioning heat dissipation modules

Industrial Heat Exchange: Various condensers and cooling coils

Why Choose MC Aluminum Hydrophilic Aluminum Foil?

From raw material selection to finished product delivery, the performance stability of hydrophilic aluminum foil depends heavily on precise production control.

1.Strict Base Material Control: High-purity aluminum substrates ensure uniform rolling surfaces and low pinhole rates

2.Mature Coating System: Stable hydrophilic contact angle and strong adhesion ensure long-term performance without rapid degradation

3.Online Inspection and Batch Traceability: Full-process monitoring of thickness, coating weight, and surface quality ensures batch-to-batch consistency

4.Customization Support: Thickness, alloy, coating color, and coil weight can be tailored to meet specific equipment requirements