Market Prospects of PTP Aluminum Foil

Between 2025 and 2035, the global market for PTP aluminum foil used in pharmaceutical packaging is expected to experience significant growth, with the market value projected to reach several hundred million USD.

In comparison, the Chinese pharmaceutical packaging market is expanding at an even faster pace, with an annual growth rate exceeding 10%, well above the global average.

The pharmaceutical aluminum foil sector is currently undergoing an unprecedented growth phase. Global demand for aluminum foil used in blister packaging has already exceeded 7,000 tons per year, and this figure is expected to continue rising.

The primary drivers behind this growth include the expansion of the global pharmaceutical industry and ongoing innovation in packaging formats. As global populations age and health awareness increases, pharmaceutical consumption continues to rise steadily, directly stimulating demand for high-performance pharmaceutical packaging materials.

As one of the world's largest pharmaceutical manufacturing countries, China shows a distinct growth trajectory. Industry data indicate that China's pharmaceutical packaging market has reached approximately USD 1.8 billion in output value, maintaining an annual growth rate of over 10%.

Material Analysis of PTP Aluminum Foil

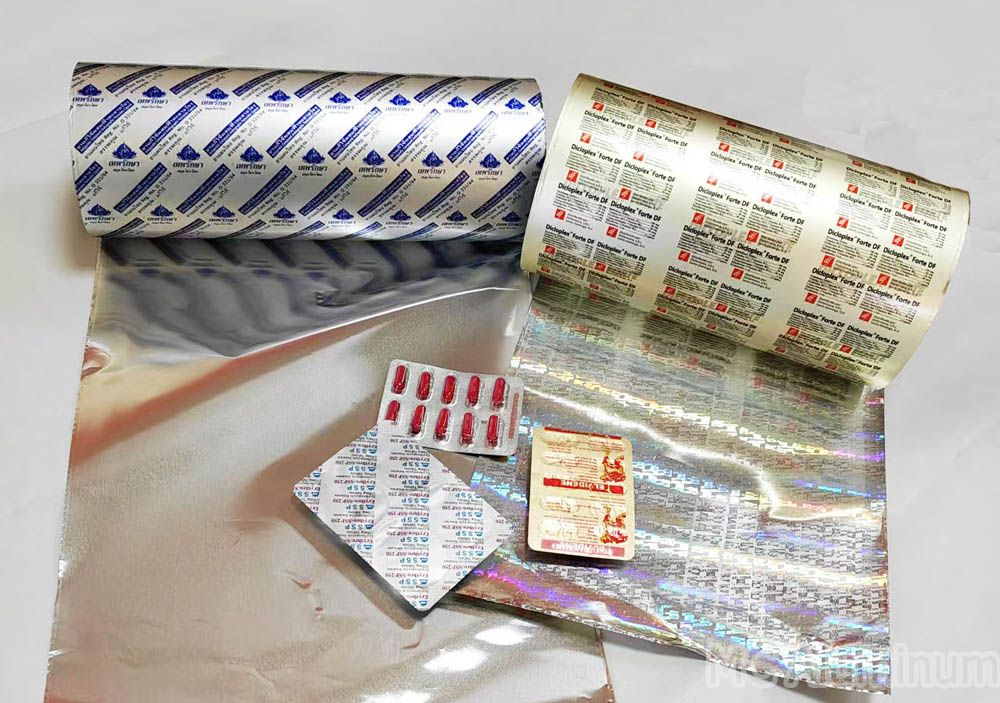

PTP aluminum foil used in pharmaceutical packaging is typically manufactured from hard aluminum foil and serves as a critical sealing material widely applied in the pharmaceutical industry, particularly for tablet and capsule blister packaging.

PTP foil generally consists of a thin aluminum foil substrate, with a heat-seal coating laminated on the side in contact with the drug, compatible with forming films such as PVC or PVDC, or other aluminum–plastic blister systems. This structure ensures optimal performance during forming, heat sealing, and end use.

PTP aluminum foil effectively reduces the risk of drug degradation caused by moisture, oxygen, and light exposure. Its push-through opening mechanism produces visible damage when accessed, offering excellent tamper-evidence and enhancing medication safety.

In addition, PTP foil is lightweight and easy to process, helping to reduce overall packaging and logistics costs. Its surface is well suited for various printing technologies, enabling clear display of branding, batch numbers, dosage instructions, and regulatory information, thereby supporting traceability and compliance requirements in pharmaceutical packaging.

Common Aluminum Foil Alloys for Pharmaceutical Packaging

Based on alloy composition and performance characteristics, aluminum foil used for pharmaceutical packaging is mainly divided into three types: 8079 aluminum foil, 8021 aluminum foil, and 8011 aluminum foil.

Among them, 8011 aluminum foil, commonly referred to as PTP aluminum foil, is the most widely used material in pharmaceutical blister packaging.

The typical thickness range of 8011 PTP aluminum foil is 0.016-0.04 mm, ensuring reliable barrier performance while remaining easy to puncture, allowing patients to remove medication conveniently.

Structure of PTP Aluminum Foil

| Structure | Thickness | Weight | Max. Width |

| Primer 1.0 gsm / Alu 20 μm / HSL 3–7 gsm | 24 ±1 μm | 60 ±3 gsm | 800 mm |

| Primer 1.0 gsm / Alu 25 μm / HSL 3–7 gsm | 29 ±3 μm | 74 ±4 gsm | 800 mm |

| Primer 1.0 gsm / Alu 25 μm / HSL 3–7 gsm | 29 ±2 μm | 74 ±3 gsm | 800 mm |

PTP Aluminum Foil Product Specifications

| Alloy | 8011 / 8021 / 8079 |

| Temper | O (Soft) |

| Thickness | 20-30 μm |

| Widht | 100-1600mm |

| Tensile Strength | 60-100 MPa |

| Elongation | ≥ 6% |

| Pinholes | ≤ 1 per m² |

| Heat Seal Strength | 6-10 N / 15 mm |

| Barrier Properties | Excellent resistance to moisture, oxygen, and light |

| Surface Treatment | Single-side or double-side coating |

| Printability | Excellent |

| Standards Compliance | USP / EP / ISO |

| MOQ | 1-3 tons |

Key Advantages of PTP Blister Foil

1.Excellent Barrier Performance

PTP aluminum foil provides outstanding protection against moisture, oxygen, and light, effectively extending shelf life and ensuring pharmaceutical stability.

2.Reliable Forming and Opening Performance

The foil exhibits stable ductility during blister forming while allowing clean, controlled rupture during push-through opening, improving patient usability.

3.Compatibility with High-Speed Packaging Lines

With a smooth surface and uniform thickness, PTP foil is ideal for high-speed automated blister packaging, helping pharmaceutical manufacturers enhance production efficiency.

4.Compliance with Pharmaceutical Regulations

Pharmaceutical-grade PTP aluminum foil typically complies with USP, EP, ISO, and other international regulatory standards, meeting global compliance requirements.

Printed Aluminum Foil for Blister Packaging

MC Aluminum supplies high-quality printed PTP blister aluminum foil, supporting up to five-color printing (4/1 or 3/2) and enabling both single-side and double-side printing to meet pharmaceutical packaging requirements for clarity and brand presentation.

Before mass production, printing artwork must be confirmed and dedicated printing cylinders prepared. If customers do not have finalized artwork, original samples or clear images can be provided as references. MC Aluminum will create printing drafts for approval before proceeding with sampling and bulk production.

Printing cylinders can be retained for repeated use in future orders with identical designs. If any changes are made to the artwork-such as text, numbers, or layout-a new printing cylinder will be required.

MC Aluminum's printing cylinders are manufactured by experienced professional partners, ensuring high precision, durability, and excellent batch consistency, supporting stable long-term mass production.

Due to plate-making and multi-color printing processes, printed PTP aluminum foil is priced slightly higher than plain foil. For detailed quotations or technical support, please feel free to contact us.

Future Development Trends of PTP Aluminum Foil

Looking ahead, technological innovation in PTP aluminum foil is expected to focus on three main directions:

1.Smart Sensing

By integrating flexible circuits, PTP foil may enable "open-and-record" functionality, transmitting medication usage data to doctors or mobile apps via Bluetooth.

2.Child-Resistant & Senior-Friendly Design (CR/SF)

Development of structures that require specific opening actions to prevent child access, while remaining easy to use for elderly patients.

3.Ultra-Thin Foil Development

Maintaining high barrier performance while reducing thickness from the mainstream 0.02 mm toward lighter, more environmentally friendly solutions.