In automotive thermal management systems, the efficiency of the radiator directly affects engine longevity and overall vehicle performance. Hydrophilic aluminum foil, as the core material of radiator fins, has become an indispensable choice in modern automotive manufacturing due to its specialized surface treatment technology.

What is Hydrophilic Aluminum Foil?

Hydrophilic aluminum foil is a high-end aluminum material with a chemical pre-treatment and a hydrophilic coating (usually organic or inorganic) applied to the foil surface. The hydrophilic coating allows condensate water to spread quickly across the fin surface, forming a thin water film instead of droplets. This eliminates the "water bridge" effect and reduces corrosion and noise caused by droplet adhesion.

Common alloy grades include 8011, 3003, and 3102, with 3102 alloy being the most widely used in automotive radiators due to its excellent anti-rust performance.

Key Advantages

1. High Heat Exchange Efficiency: The hydrophilic coating reduces airflow resistance, prevents condensate blockage in heat transfer channels, and improves thermal efficiency by 15%-25% compared to ordinary aluminum foil.

2. Excellent Corrosion Resistance: Automotive environments frequently face salt spray, acid rain, and humid heat. The hydrophilic coating passes rigorous salt spray tests, significantly extending radiator service life.

3. Mold and Odor Resistance: The surface coating inhibits bacterial growth, effectively preventing odor formation in automotive AC systems.

4. Stable Processing: Excellent coating adhesion and lubricity ensure no powdering or sticking during high-speed stamping of fins.

Technical Specifications

| Alloy Grades | 1100 / 3003 / 3102 / 8011 |

| Temper | O / H22 / H24 |

| Thickness | 0.08 - 0.20 mm |

| Width | Customized per client requirements |

| Surface Treatment | Hydrophilic coating |

| Hydrophilic Grade | ≥ Class A |

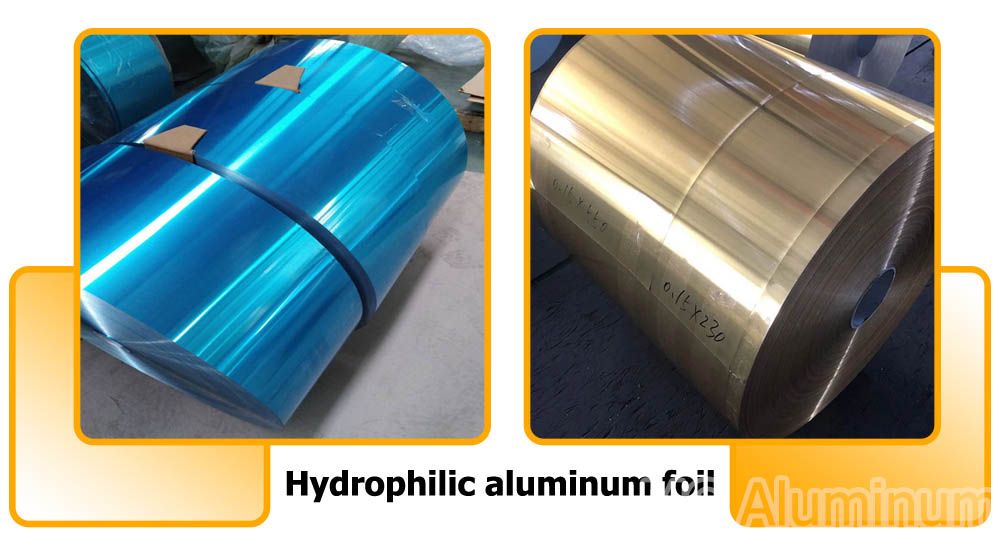

| Coating Type | Blue / Transparent / Gold hydrophilic coating |

| Coating Thickness | 1.0 - 2.5 μm |

| Salt Spray Resistance | ≥ 500 hours (customizable) |

| Applicable Standards | ASTM / EN / JIS |

| MOQ | 1-3 tons |

Manufacturing Process

High-Quality Aluminum Ingots Casting

Use high-purity aluminum or alloy ingots to ensure material consistency and stability.

Hot Rolling + Cold Rolling

Precisely control thickness, tolerances, and surface flatness.

Annealing Treatment

Improve foil flexibility and formability to meet fin manufacturing requirements.

Surface Degreasing and Cleaning

Ensure a clean surface for optimal coating adhesion.

Hydrophilic Coating Application

Apply the coating using roller or spray methods to form a uniform, stable hydrophilic layer.

High-Temperature Curing and Quality Testing

Ensure coating adhesion, hydrophilicity, and corrosion resistance meet specifications.

Application Fields

Automotive Radiators: Core material for radiator fins, ensuring stable engine temperature.

Electronic Heat Dissipation: Used in power adapters and circuit board cooling.

Industrial Equipment: For engine cooling and heat dissipation in metalworking machinery.

Packaging and Transportation

Roll Packaging: Each roll weighs 500-1000 kg, protected with moisture-proof paper and plastic film.

Sheet Packaging: Each sheet wrapped in anti-static foam and packed in wooden crates.

FAQ

Q1: What is the service life of hydrophilic aluminum foil?

A: Typically 8-10 years, significantly longer than conventional aluminum foil, which lasts 3-5 years.

Q2: How is hydrophilic aluminum foil installed in automotive radiators?

A: Attach the foil closely to the radiator tubes and secure it with heat-shrink adhesive to ensure no gaps.

Q3: How is hydrophilic aluminum foil priced?

A: Priced according to specifications. Generally 10-20% higher than ordinary aluminum foil, but the longer lifespan results in lower overall cost.