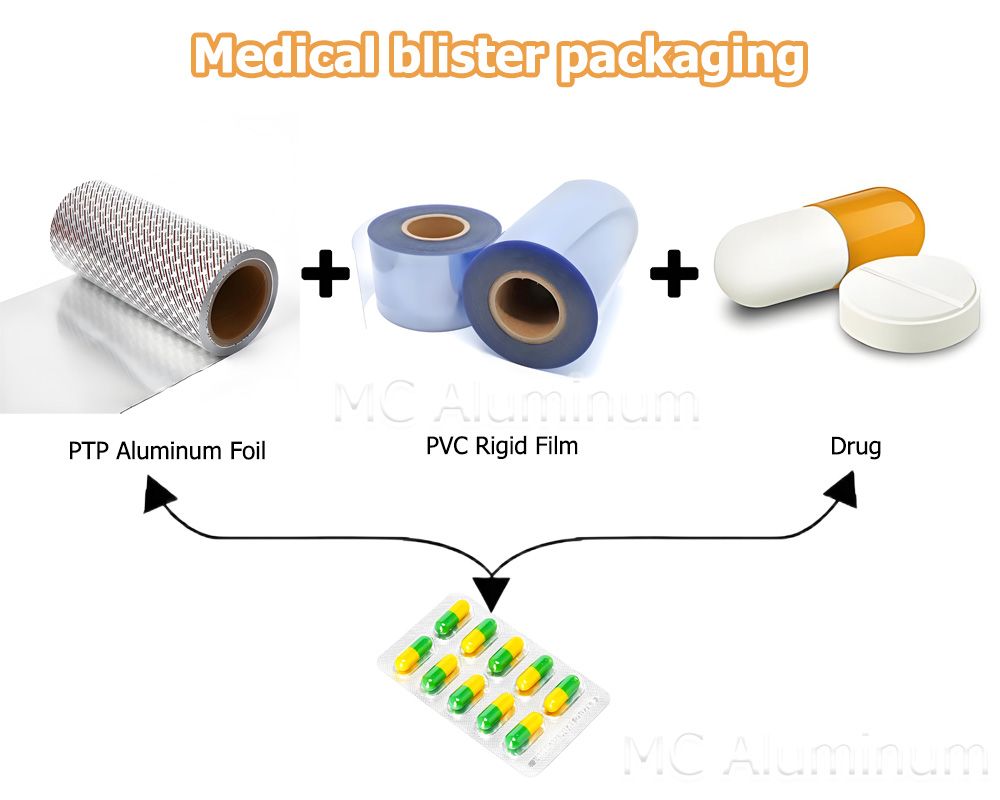

In the field of modern pharmaceutical packaging, the lamination of PTP foil (Press Through Package Aluminum Foil) and PVC (polyvinyl chloride) is widely used for solid dosage blister packaging. This laminated structure not only provides excellent barrier performance and mechanical strength but also meets the comprehensive requirements of pharmaceutical packaging for safety, convenience, and cost control.

Introduction to PTP Foil and PVC Lamination

PTP aluminum foil usually consists of a thin layer of aluminum foil coated with a heat-seal lacquer, typically with a thickness of 20–30 microns. It is a key component of blister packaging, offering outstanding moisture-proofing, light-shielding, and oxygen-barrier properties. As an excellent barrier material, aluminum foil effectively blocks moisture, oxygen, and UV rays from affecting medications, thus ensuring drug stability, efficacy, and shelf life.

PVC rigid film serves as the forming base of the blister cavity and has good thermoplasticity, transparency, and mechanical strength. Through thermoforming processes, PVC can easily be shaped into various cavity sizes to accommodate different tablets and capsules. When the filled PVC blister is sealed with PTP aluminum foil using heat-sealing technology, a sealed blister pack is formed to protect the medication during storage and transportation.

Laminated Structure:

Medicine → PVC Forming Film → Tablet/Capsule → PTP Aluminum Foil Cover Film (heat seal layer facing down)

After lamination, users can retrieve the medication by pressing through the aluminum foil, hence the name "Press Through Package."

PTP Aluminum Foil and PVC Rigid Film Lamination Process

| Material Preparation | PVC Film: Typically 200–250 microns thick, requiring good thermoformability. |

| PTP Foil: Coated with heat-sealing lacquer compatible with PVC. | |

| Thermoforming | Blister cavities are formed on the PVC film using vacuum or pressure. |

| Filling Tablets | Tablets are loaded into the blister cavities via vibration or conveyor systems. |

| Heat Sealing | PTP foil is laid over the filled cavities and heat-pressed at 120–160°C to form a firm seal between the layers. |

| Cutting and Packaging | Laminated sheets are die-cut into individual or multi-dose blister packs. |

Key Advantages of Pharmaceutical Blister Packaging

1.Excellent Barrier Properties: Aluminum foil effectively protects medication from environmental factors.

2.High Transparency (PVC part): Allows users to view the medication clearly, aiding proper use.

3.Good Mechanical Strength: Prevents physical damage to the product during transport and storage.

4.Cost-Effective: PVC and aluminum foil are relatively inexpensive compared to other high-barrier materials.

5.Mature Production Process: Widely used in the industry with high efficiency and proven technology.

6.Ease of Use: "Press-through" design makes it easy for patients to access medication, with potential child-resistant features.

Technological Innovation: Evolving Beyond Tradition

1. Enhanced Barrier Properties:

PVDC Coating: Applying PVDC on PVC significantly improves its moisture and oxygen barrier capabilities—ideal for moisture-sensitive drugs.

PCTFE Lamination: For drugs extremely sensitive to moisture and oxygen, PVC/PCTFE laminated films offer superior protection (though at a higher cost).

Co-extrusion Technology: Combining PVC with high-barrier polymers like EVOH to improve performance while controlling costs.

2. Sustainability and Eco-Friendly Development:

Recyclable & Biodegradable Materials: Exploring alternatives like PET, PP, PE, and bio-degradable polymers to reduce environmental impact.

Material Reduction: Optimizing design and production to reduce material use.

Life Cycle Assessment: Identifying and optimizing environmental impacts across the product life cycle.

3. Integration of Smart & Functional Packaging:

Anti-Counterfeiting & Traceability: Integration of security printing, QR codes, RFID, etc., to improve supply chain transparency.

Medication Compliance: Blister packs with calendar features or reminders to assist patient adherence.

Sensor Integration: Future innovations may include sensors to monitor storage conditions.

4. Intelligent and Automated Manufacturing:

Precision Coating Technology: Ensures even and reliable heat-seal coating.

In-line Quality Control: Real-time monitoring to maintain product standards.

Automated Production Lines: Use of robotics to boost efficiency and reduce costs and errors.

Typical Applications

Regular tablets (e.g., vitamins, pain relievers)

Capsules (e.g., antibiotics, nutritional supplements)

Fast-release dosage forms

Medications with low high-temperature stability requirements

MC Aluminum is a professional manufacturer of pharmaceutical packaging materials, producing 8011 aluminum foil, 8079 aluminum foil, PTP aluminum foil, Alu-Alu foil, PVC rigid films, PVC/PVDC composite films, and more. These are suitable for packaging tablets, capsules, and granules. With a rich product lineup, hygienic and safe standards, and exports to over 40 countries and regions, MC Aluminum is trusted by global customers. You can order with confidence.