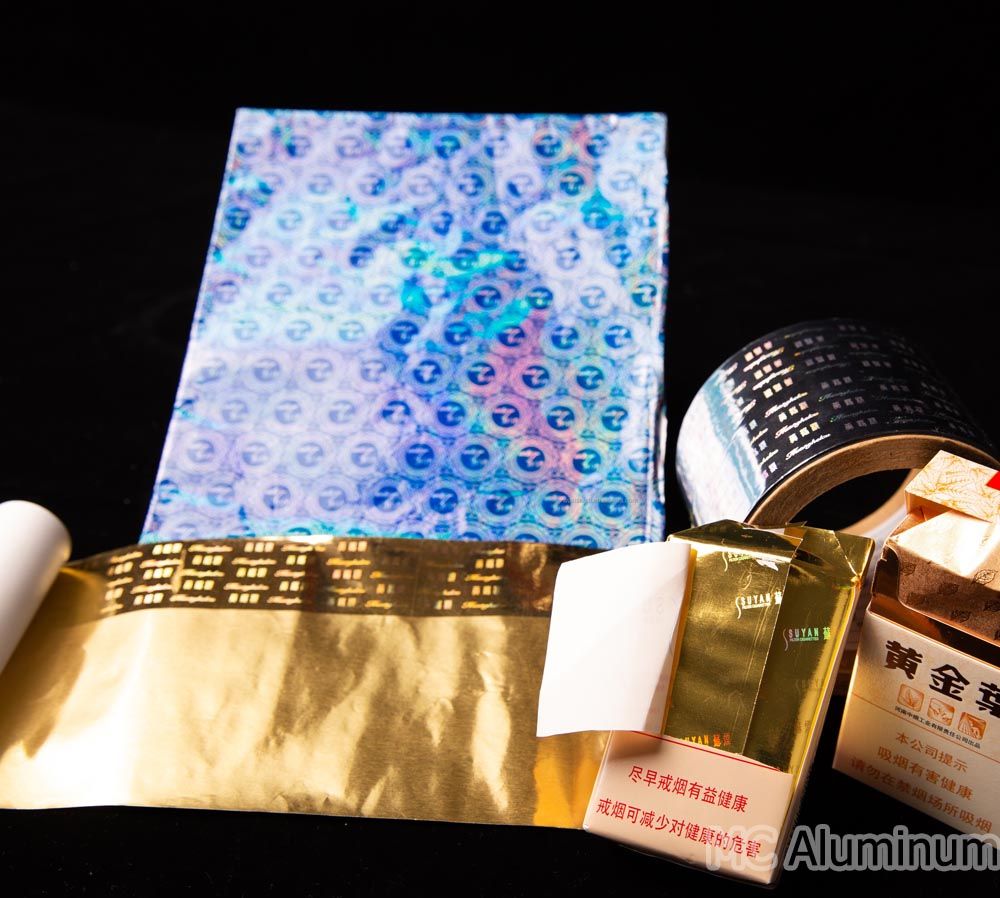

In the tobacco industry, laser holographic inner liner aluminum foil paper has become one of the preferred materials for mid- to high-end cigarette packaging and is widely used in many premium brands. Its excellent barrier properties ensure effective moisture resistance and aroma preservation, while the high gloss and dazzling holographic effects significantly enhance product appeal and premium image. The complex manufacturing process also provides excellent anti-counterfeiting performance.

Detailed Introduction

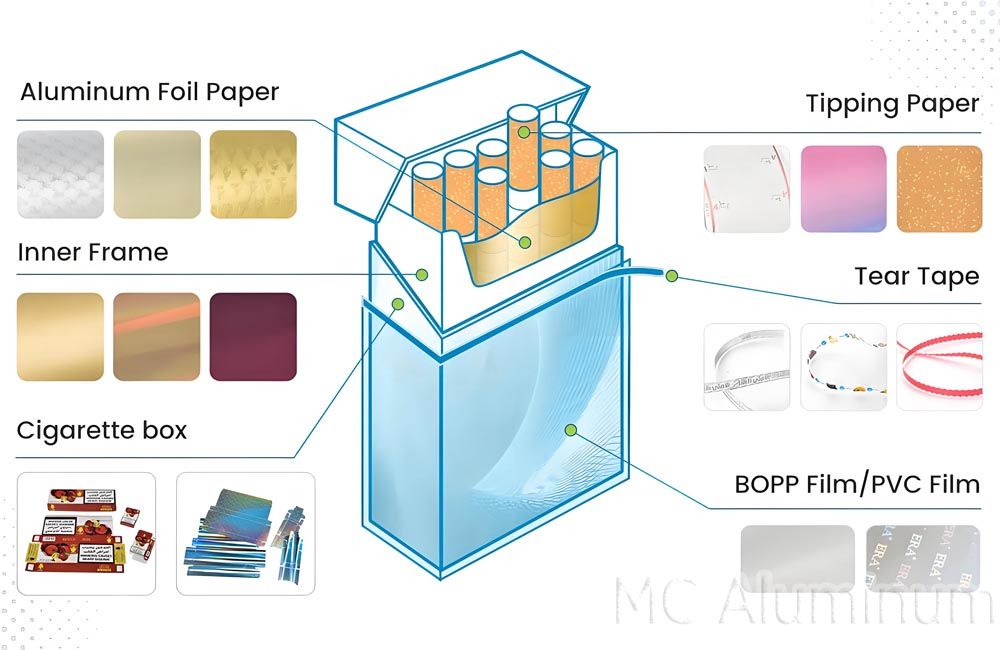

The cigarette inner liner is the material placed between the inner layer of the cigarette pack and the cigarette sticks. Its primary functions are to block air, resist moisture, and preserve aroma.

The term "laser holographic" refers to micro-nano structures formed on the aluminum foil surface through laser engraving or embossing, creating dynamic and three-dimensional optical effects.

When combined, these technologies produce an inner liner foil paper that offers metallic luster, holographic visual effects, anti-counterfeiting capabilities, and superior barrier performance. This type of material is commonly used for mid-to-high-end cigarette brands, such as soft packs, premium editions, limited editions, or commemorative products, helping strengthen brand identity and market competitiveness.

Laser Holographic Technology

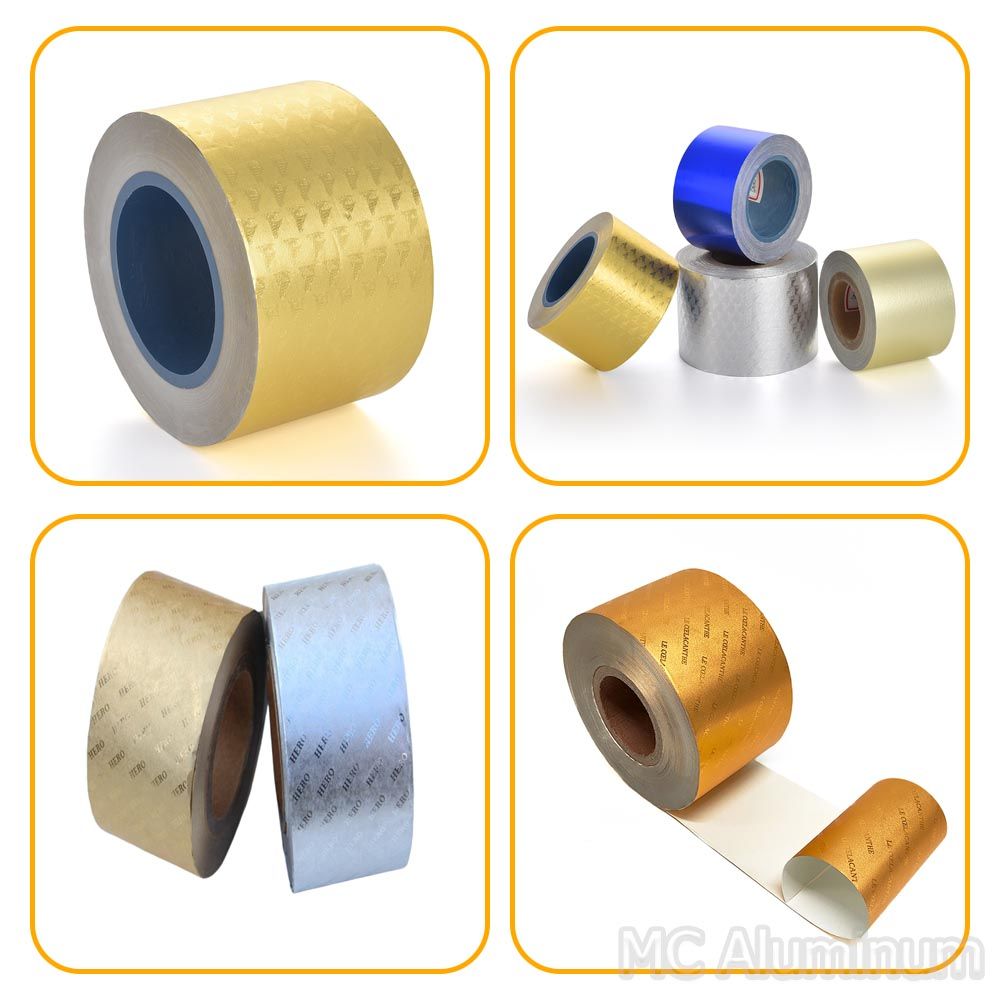

Laser holography is the key feature that differentiates this foil paper from ordinary plain aluminum foil. Using micro-nano embossing technology, extremely fine diffraction grating structures are created on the material surface producing vivid optical effects without the need for ink.

1. Striking Visual Impact & Differentiation

When illuminated, the inner foil displays dynamic rainbow-like holographic effects with vivid colors and a three-dimensional appearance. This greatly enhances the visual impact when the cigarette pack is opened, reinforcing the premium and high-quality perception.

2. Enhanced Brand Recognition

Brand logos, customized patterns, and specific holographic elements can be embedded directly into the foil. As consumers repeatedly see these visual markers during use, brand recognition and luxury perception are naturally reinforced.

3. Flexible Customization

Holographic technology supports extensive customization options. Whether it is complex micro-patterns, dynamic effects, or brand-specific images, all can be precisely replicated to meet the diverse needs of global tobacco brands.

Core Functions of Cigarette Inner Liner Aluminum Foil Paper

Outstanding Barrier Performance

The aluminum foil layer provides near-perfect resistance to water vapor and gases.

This effectively isolates the tobacco from external humidity and oxygen, maintaining the optimal moisture content and smooth flavor profile of cigarettes.

Aroma Preservation

The dense metallic structure prevents the evaporation of natural aromatic compounds in the tobacco, ensuring that consumers experience a fresh and authentic tobacco scent when they open the pack.

Excellent Heat-Sealing Properties

After surface treatment, the foil paper exhibits reliable heat-sealing performance. This ensures efficient and stable sealing during high-speed automated cigarette packaging, improving production efficiency.

Manufacturing Process

1. Aluminum Foil Base Material Production

High-purity 8011 or 1235 aluminum foil is produced through melting, casting, cold rolling, and annealing to form ultra-thin foil suitable for tobacco packaging.

2. Surface Treatment

The aluminum foil undergoes cleaning, coating, or priming to enhance adhesion and optimize optical performance.

3. Holographic Pattern Formation

Holographic effects are created using one or a combination of the following technologies:

Embossed holography

Laser engraving

Diffraction grating embossing

Customized logo holographic imaging

4. Aluminum Foil and Paper Lamination

Using food-grade adhesive, the foil is laminated with paper on a high-speed solvent-free laminator to ensure foil strength and maintain optical clarity.

5. Drying and Curing

Temperature and tension are precisely controlled to enhance bonding stability and prevent deformation.

6. Slitting, Inspection, and Packaging

The finished foil paper is inspected for thickness, tensile strength, appearance, gloss, and holographic clarity before packaging and shipment.