Laminated cigarette aluminum foil paper is a multi-layer composite material produced by bonding aluminum foil with paper or other substrates through specialized lamination processes. It is typically used inside cigarette packs, directly wrapping the cigarettes to provide barrier protection and product preservation.

Basic Structure of Laminated Cigarette Foil Paper

Aluminum Foil Layer:

Thickness typically ranges from 6.0 μm to 7.0 μm, serving as the primary barrier against moisture, oxygen, and odor transmission.Paper Liner Layer:

Made from high-strength paper or specially coated paper, suitable for printing brand logos, tax markings, or anti-counterfeiting patterns.Adhesive Layer:

Bonds the aluminum foil and paper substrate firmly together, preventing delamination.

Through lamination, this composite material combines the excellent barrier performance of aluminum foil with the mechanical strength and processability of paper, achieving an optimal balance of functionality. Thickness, coating, and composite structure can be customized according to brand and packaging requirements.

Technical Specifications of Cigarette Inner Liner Aluminum Foil

| Product Name | Cigarette Aluminum Foil, Tobacco Foil, Aluminum Foil for Cigarette Packaging, Flexible Packaging Foil |

| Alloy | 1235 / 8011 / 8079 |

| Temper | O |

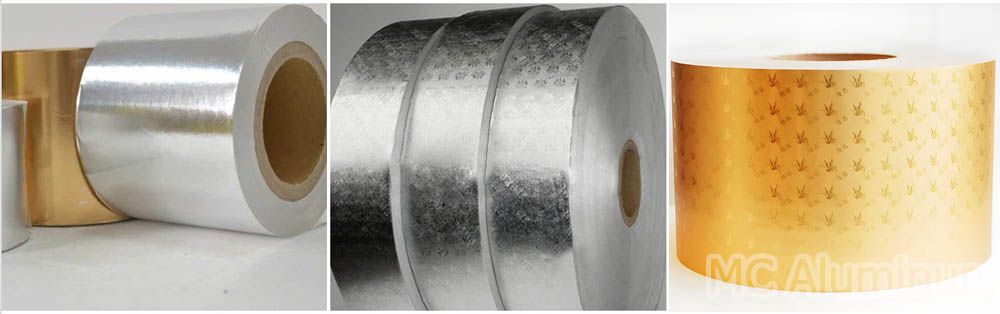

| Color | Gold, Silver (or customized) |

| Width | 100 mm - 1500 mm |

| Thickness | 0.0055 mm - 0.03 mm |

| Inner Diameter | 76 mm, 152 mm (or customized) |

| Outer Diameter | 250 mm - 300 mm (or customized) |

| Special Requirements | Acceptable |

| Embossing Patterns | Fine grid, chocolate pattern, star, dot, tulip, grid, large grid, coin, peony, bubble |

| Packaging | Rolls placed on solid wooden pallets, packed in wooden cases or cartons and secured with metal or plastic straps |

| MOQ | 1-3 tons |

Cigarette Inner Liner Foil Parameters

| Foil Color | Gold, Silver |

| Foil Thickness | 6 μm |

| Aluminum Foil Weight | 20 g/m² |

| Paper Weight | 25-80 g/m² |

| Adhesive Weight | 0.5 g/m² |

| Total Thickness | 4.5-8.0 μm |

| Total Weight | 45-80 g/m² |

| Coefficient of Friction | < 0.18 |

| Paper Core Diameter | 59.5 mm or 60.5 mm |

Seven Key Functions of Cigarette Inner Liner Aluminum Foil

1.Aroma Preservation

Tobacco aromas consist of highly volatile organic compounds. Aluminum foil's near-zero permeability effectively locks in flavor and fragrance, preventing aroma loss.

2.Moisture Barrier

Prevents external moisture ingress, protecting tobacco from mold and deterioration.

3.Light Blocking

Aluminum foil provides 100% light shielding, protecting tobacco from UV-induced degradation.

4.Decorative Value

Classic gold and silver finishes, along with customized embossed logos and patterns, enhance brand identity and premium appearance.

5.Packaging Machine Runnability

The paper layer provides stiffness and controlled friction, ensuring stable folding and heat sealing on high-speed cigarette packing machines.

6.Environmental Friendliness and Recyclability

Both aluminum foil and paper are recyclable, supporting sustainable packaging trends.

7.Anti-Counterfeiting and Brand Protection

Printing, embossing, and laser coding enhance visual appeal while strengthening brand recognition and anti-counterfeiting performance.

Lamination Processes

| Process Type | Characteristics | Typical Applications |

| Thermal Lamination | Uses heat and pressure for strong bonding | Heavy-duty packaging, rigid cigarette box liners |

| Adhesive Lamination | Uses hot-melt adhesives (PE, EVA); flexible and controllable | Flexible packaging, high-precision printed surfaces |

| Co-Extrusion Lamination | Aluminum foil co-extruded with plastic film, then bonded to paper | High-barrier e-cigarette packaging |

Production Process of Cigarette Inner Liner Aluminum Foil

The production process directly determines the quality and performance of laminated cigarette foil paper and typically includes:

Raw material preparation

Aluminum foil surface treatment

Adhesive coating

Lamination and compression

Coating and surface finishing (optional)

Slitting and rewinding

Application Areas of Laminated Aluminum Foil Paper

Cigarette Inner Wrapping

Directly wraps cigarettes to preserve aroma and prevent moisture ingress.

Premium Cigarette Box Inner Packaging

Combined with paperboard or rigid boxes to enhance packaging quality.

Anti-Counterfeiting Packaging Materials

Printing, laser coding, and surface texturing improve brand security.

Export and Long-Term Storage Cigarettes

Essential barrier and sealing performance for long-distance transportation and export markets.

Future Trends and Innovations

Smart Packaging

RFID Integration: Embedding RFID chips into paper substrates for tracking and authentication.

Color-Changing Inks: Combined with aluminum foil to indicate temperature or humidity changes for anti-counterfeiting purposes.

Biodegradable Materials

Development of laminated materials using bio-based polymers to further reduce environmental impact.

Customized Solutions

Tailored packaging designs with varying thicknesses, embossing patterns, and functional features to meet specific brand requirements.