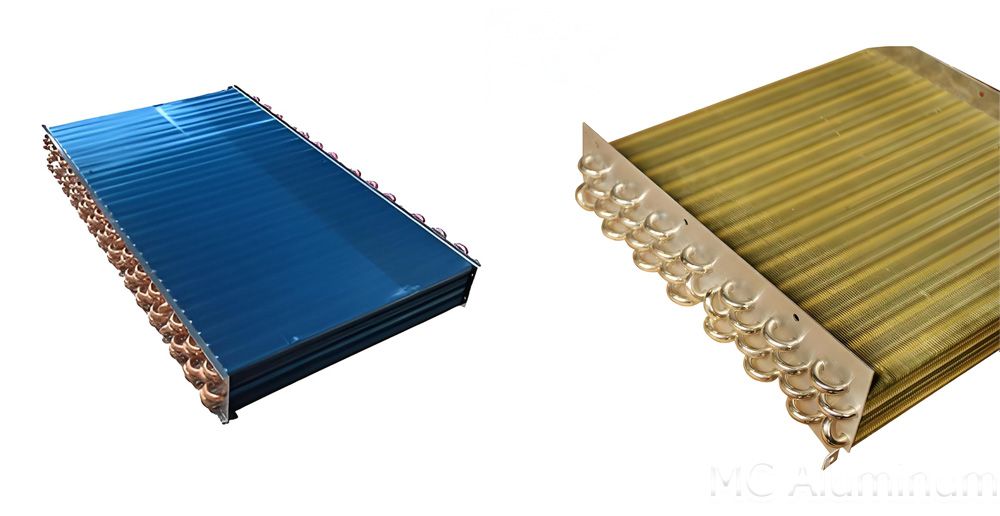

In modern refrigeration and HVAC (Heating, Ventilation, and Air Conditioning) systems, the heat exchanger is the heart of the unit, and its efficiency largely depends on a set of precision components-fins. These ultra-thin, densely arranged aluminum foils act as the bridge for heat transfer. Among them, 3102 aluminum foil and 8011 aluminum foil with specialized coatings stand out as the preferred materials for manufacturing high-performance and reliable heat exchanger fins.

3102 Aluminum Foil

3102 aluminum foil belongs to the Al-Mn (aluminum-manganese) alloy series. The addition of manganese significantly enhances solid solution strengthening, giving the foil higher strength and excellent deep drawing properties even in the annealed (O) temper. It is widely used in high-efficiency heat exchangers that require superior strength and formability, such as inverter air conditioners for both indoor and outdoor units.

8011 Aluminum Foil

8011 aluminum foil is an Al-Fe-Si (aluminum-iron-silicon) alloy. Compared with 3102, it offers higher strength and hardness, which means fins can better resist collisions and deformation during manufacturing, transportation, and installation. This ensures stable spacing, reduces air resistance, and improves durability. It also has slightly better corrosion resistance. 8011 foil is commonly used in commercial air conditioners, automotive heat exchangers, and cost-sensitive household AC models.

In the actual heat exchange process, the fins will be exposed to moisture and pollutants in the air, which can easily cause corrosion or water accumulation, thus greatly reducing efficiency. Therefore, the fin aluminum foil needs to be surface coated:

(1) Hydrophilic coated aluminum foil

Hydrophilic aluminum foil is the most common coated aluminum foil in air conditioners. A layer of hydrophilic coating is applied to the surface of the aluminum foil. The hydrophilic coating allows water droplets to spread on the surface of the fins, forming a water film instead of condensing into water droplets. This effectively prevents water droplets from blocking the air flow channel and improves heat exchange efficiency. The coating isolates the aluminum material from corrosive substances in the condensed water, extending the service life of the fins. Even under low-temperature operating conditions, it helps to reduce frost.

(2) Hydrophobic coated aluminum foil

Hydrophobic aluminum foil is mainly used in places with higher corrosion protection requirements, such as coastal areas or special industrial environments. Its surface is coated with a coating that is hydrophobic (repelling water) or more resistant to acid and alkali corrosion. It has excellent corrosion resistance and self-cleaning properties.

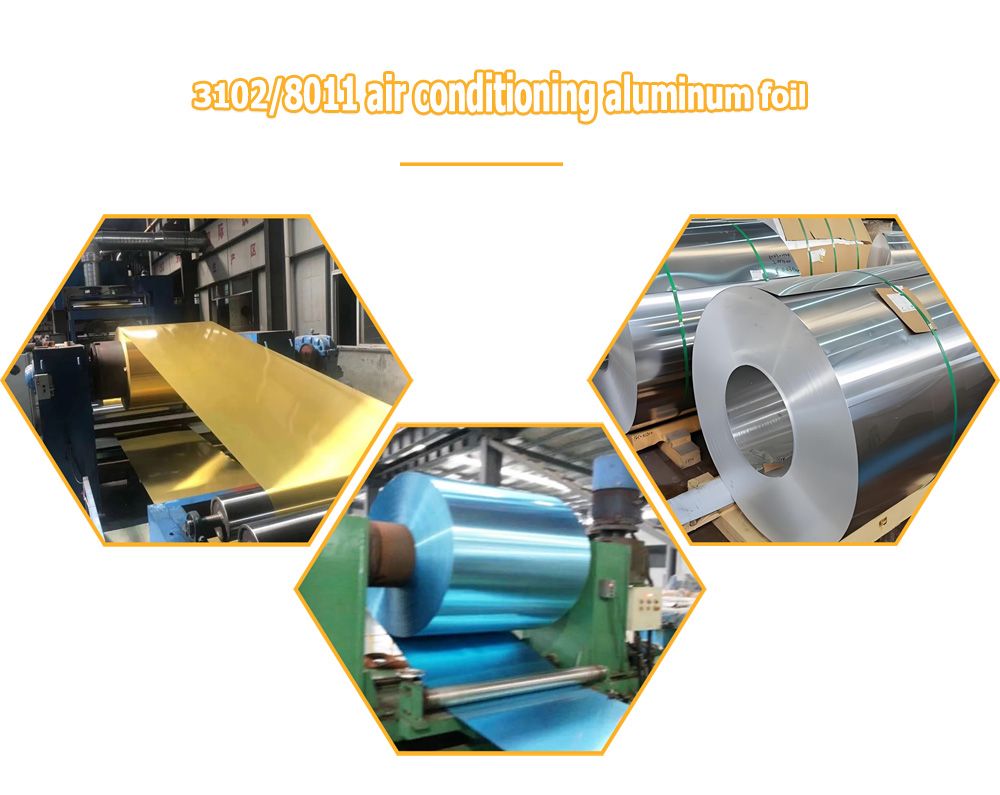

Product Specifications for Air Conditioning Aluminum Foil

| Alloys | 3102, 8011, etc. |

| Temper | H22, H24, H26 |

| Thickness range | 0.08 mm - 0.20 mm |

| Width range | 100 mm - 1400 mm (customizable) |

| Length range | 100 mm - 6000 mm (customizable) |

| Coating types | Epoxy coating, polyester coating, hydrophilic coating, hydrophobic coating |

| Colors | Transparent, blue, gold (hydrophilic foil commonly in blue or gold) |

| Sample | Available |

| Packaging | Standard seaworthy packaging |

| MOQ | 1-3 tons |

Key Advantages of 3102/8011 Aluminum Fin Foil

1. Excellent thermal conductivity : second only to copper, but lighter and more cost-effective.

2.Lightweight : reduces overall equipment weight compared to copper fins.

3.Outstanding formability : easy to punch into complex fin structures (corrugated, bridge, louver, etc.) to enhance turbulence and improve heat exchange.

4.Good corrosion resistance : natural oxide layer plus protective coatings extend service life.

5.High cost-performance ratio : lower cost than copper while maintaining comparable or superior performance.

6.Eco-friendly and recyclable : supports sustainable and green manufacturing.

Applications

3102/8011 coated aluminum foil for heat exchanger fins is widely used in:

Household air conditioners: evaporator and condenser fins

Commercial air conditioners: central AC units, cold storage heat exchangers

Automotive air conditioning: condensers, heaters, evaporators

Refrigerators and freezers: condenser and evaporator fins

Air source heat pumps: outdoor unit heat exchanger fins

Manufacturing Process

Base material preparation : 3102 or 8011 aluminum alloys are melted, cast, hot-rolled, and cold-rolled to target thickness (0.08–0.15 mm).

Surface pretreatment : degreasing and chemical conversion to form a nano-level conversion film for better coating adhesion.

Precision coating : roller-coating technology applies epoxy, polyester, or acrylic-based coatings evenly onto the foil surface.

High-temperature curing : the foil passes through a curing furnace, crosslinking the coating into a strong, dense protective film.

Recoiling and slitting : the coated foil is rewound and slit to required widths, ready for fin stamping by heat exchanger manufacturers.