The 3102 alloy belongs to the 3000 aluminum-manganese series, containing a small amount of manganese (Mn). It offers excellent formability (easy to stamp into complex fin shapes) and good corrosion resistance. In air-conditioning foil applications, 3102 is usually supplied in tempers such as H24 and H26, ensuring the fins maintain sufficient strength and rigidity.

MC Aluminum provides 3102 aluminum foil in decorative colors such as blue, golden, and green, which not only enhance product identification but also improve weather resistance.

3102 aluminum foil is widely used for the production of heat exchange fins in air conditioners, refrigerators, and other refrigeration equipment. These fins are crucial for increasing heat exchange surface area, ensuring efficient cooling and heating in HVAC systems.

3102 hydrophilic aluminum foil effectively resists corrosion from environmental agents, extending the service life of air-conditioning units. This is particularly important in marine climates or industrial areas, where the air contains higher levels of corrosive elements.

Hydrophobic Treatment Technology

Hydrophobic treatment is achieved through nanoscale surface structuring and modification with low-surface-energy materials. Common techniques include electrochemical etching to create micro-nanocomposite structures, sol-gel hydrophobic coatings, and plasma treatment. These treatments create a water contact angle greater than 90° on the aluminum foil surface, even reaching a super-hydrophobic state (contact angle >150°), thus achieving a self-cleaning effect.

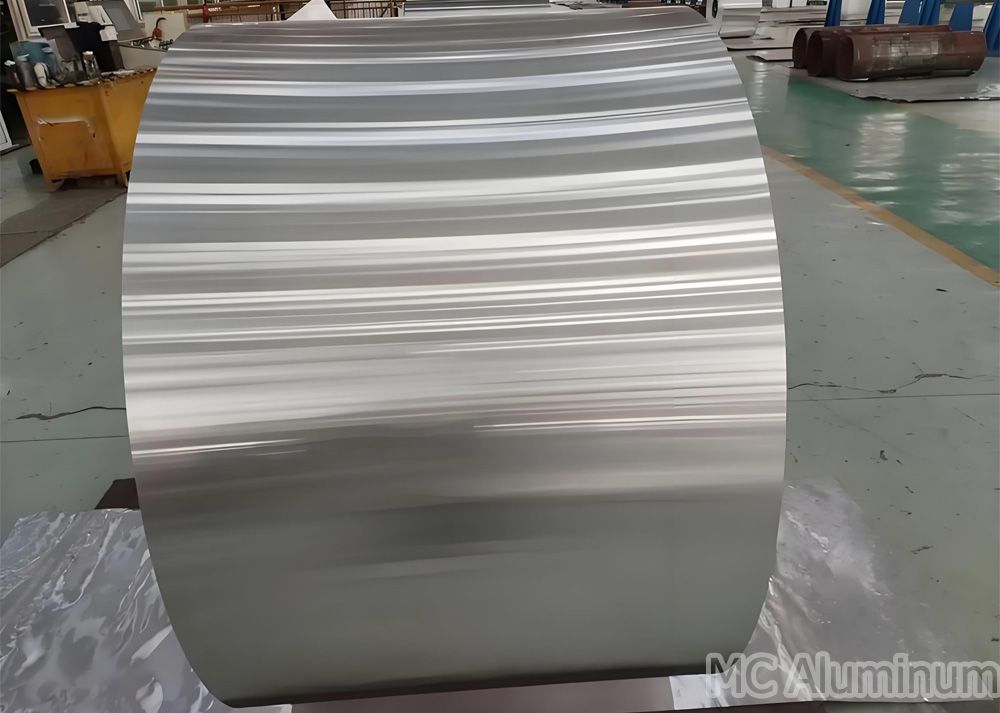

3102 Aluminum Foil Product Specifications

| Alloy | 3102 |

| Temper | H22, H24, H26, etc. |

| Thickness | 0.08 mm - 0.20 mm |

| Width | 100 - 1600 mm |

| Length | 100 - 6000 mm |

| Inner Diameter (ID) | 75 / 152 / 200 / 300 / 400 / 500 mm |

| Outer Diameter (OD) | 400 - 1100 mm |

| Surface | Mill finished / polished |

| Applications | Heat exchangers, evaporators, condensers (fin stock) |

| Samples | Available |

| MOQ | 1-3 tons |

Product Features of 3102 Hydrophilic Aluminum Foil

1. Excellent Hydrophobicity:The treated surface achieves a high contact angle with water; droplets roll off quickly, removing dust and keeping fins clean.

2. Enhanced Corrosion Resistance:The colored coating and hydrophilic treatment isolate the aluminum substrate from corrosive agents, prolonging service life, especially in hot and humid environments.

3. Anti-Microbial Properties:Reduced surface water retention inhibits mold and microbial growth, improving air quality.

4. Aesthetic Appearance:Colored surfaces (blue, golden, green) enhance the visual appeal of air conditioner components, meeting consumer demand for aesthetically pleasing products.

5. Stable Heat Exchange Efficiency:Surfaces resist dust accumulation and fouling, keeping fin gaps clear, maintaining high heat exchange efficiency, and lowering energy consumption.

6. Eco-Friendly:Coatings comply with RoHS and REACH standards, contain no harmful substances, and are recyclable.

Applications

3102 colored hydrophobic aluminum foil for air conditioners is primarily used in household and commercial air conditioners, as well as specialized air conditioning equipment (such as computer room air conditioners and cleanroom air conditioners). Heat exchangers using this material maintain high heat exchange efficiency over time, reducing energy consumption and minimizing maintenance requirements.

Quality Standards for 3102 AC Aluminum Foil

Thickness tolerance: ≤ ±0.005 mm, ensuring uniformity

Coating adhesion: Passes cross-hatch test; no peeling or blistering

Salt spray resistance: > 1000 hours with no significant corrosion spots

Hydrophobicity test: Water contact angle ≥ 105°

Bending resistance: 180° bending without cracks or peeling

Environmental compliance: Meets RoHS, REACH, and FDA requirements