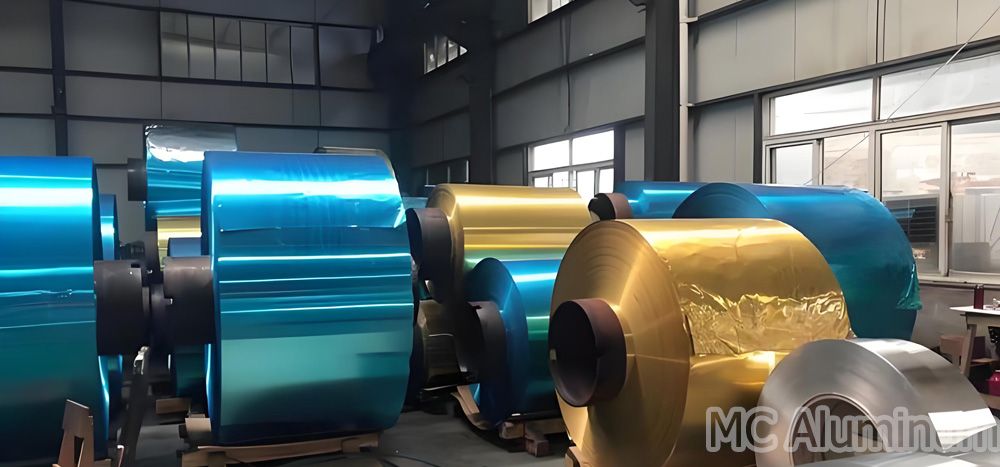

MC Aluminum is a professional manufacturer of aluminum fin stock for air conditioning equipment. Our products are widely used in heat exchangers, condensers, evaporators, and radiators. In addition to plain foil, we also produce coated hydrophilic foil and epoxy foil in different colors, such as blue, golden, black, and natural. These coated foils are extensively applied in HVAC systems.

3102 aluminum alloy belongs to the Al-Mn series and is an improved version based on 3003 alloy. It offers excellent strength, corrosion resistance, thermal conductivity, and processability, making it the preferred material for manufacturing heat exchanger fins (hydrophilic foil, plain foil).

The term “fin stock” refers to aluminum alloy thin sheets produced through hot rolling and cold rolling processes, typically with a thickness ranging from 0.08mm to 0.25mm. These thin sheets are then stamped, rolled, or shaped into corrugated or louvered fins, which significantly enhance the heat transfer efficiency between air and refrigerants in heat exchangers.

Applications of 3102 Aluminum Foil Fin Stock

Fin stock materials for coated aluminum foil are mainly used in the production of fins for heat exchangers such as air conditioner condensers and evaporators, no-frost refrigerator evaporators, finned evaporators, commercial refrigerator condensers and evaporators, as well as automotive air conditioner condensers and evaporators.

Product Information - Aluminum Fins

| Alloy | 3102 |

| Temper | O, H26, etc. |

| Thickness | 0.08mm-0.25mm |

| Width | 100-1600mm |

| Surface Roughness | 0.3-0.5 μm |

| ID | 75, 150, 300, 400mm |

| OD | As required |

| MOQ | 1-3 tons |

Mechanical Properties

| Alloy | 3102 |

| Temper | H26 |

| Tensile Strength (MPa) | 130-140 |

| Elongation (%) | ≥15% |

| Thickness Tolerance | ±3% |

| Width Tolerance | ±1mm |

| Cupping Value | ≥5.5 |

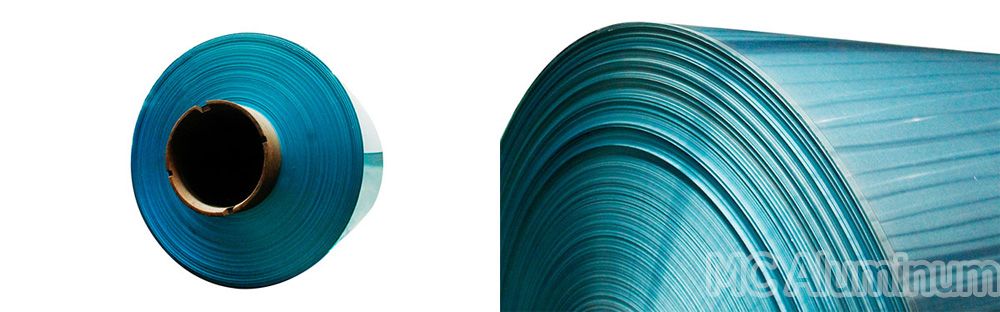

Normal Hydrophilic aluminum foil (Blue)

| Coated Laquer | Single Side Film Thickness | Hydrophilic Film Thickness of Single Side | Anticorrosive Coating | Hydrophilic Angle | Alkali Resistance |

| Hui Gu | 0.8-1.4um | 0.14-0.27um | 0.66-1.13um | ≤10° | 10%nNaOH 20minutes at 25℃ |

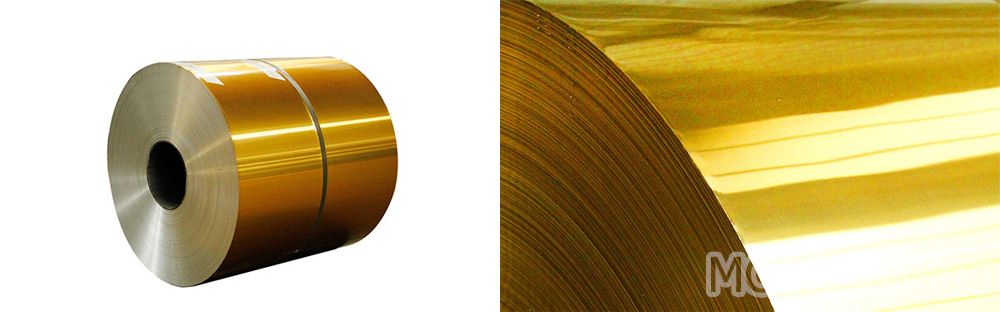

High Corrosion of Hydrophilic aluminum foil( Golden)

| Coated Laquer | Single Side Film Thickness | Hydrophilic Film Thickness of Single Side | Anticorrosive Coating | Hydrophilic Angle | Alkali Resistance |

| Hui Gu | 1.27-1.86um | 0.14-0.27um | 1.13-1.59um | ≤10° | 10%nNaOH 20minutes at 25℃ |

Performance Characteristics of 3102 Aluminum Foil

1. Excellent Corrosion Resistance

3102 aluminum alloy has strong oxidation and corrosion resistance, ensuring long-term stable performance in humid, condensing, and salt-spray environments. This is especially critical for air conditioner fins frequently exposed to air and condensation water.

2. Good Thermal Conductivity

As a material for heat exchangers, thermal conductivity is a key performance indicator. 3102 alloy features a high thermal conductivity coefficient, allowing rapid heat transfer and improved heat exchange efficiency, which ultimately reduces energy consumption.

3. Outstanding Formability

Heat exchanger fins often require complex corrugated, louvered, or perforated structures. These demand excellent material plasticity. 3102 aluminum alloy fin stock demonstrates superb stamping properties, minimizing cracking or brittle fracture during forming.

4. Lightweight Advantage

With a density only one-third of steel, fins made from 3102 aluminum significantly reduce the overall weight of heat exchangers, supporting the modern trend toward lightweight equipment.

5. Cost-Effectiveness & Environmental Friendliness

Compared with copper, aluminum offers lower cost and higher recycling efficiency. The recycling rate of scrap aluminum exceeds 90%, aligning with green manufacturing and sustainable development goals.

6. Surface Treatment Compatibility

3102 fin stock can be coated with hydrophilic or anti-corrosion layers to enhance heat transfer efficiency, as seen in hydrophilic foil applications.

Quality Control in 3102 Aluminum Fin Foil Production

Thickness Tolerance: Strictly controlled, usually within ±0.005mm

Surface Quality: Smooth, free from scratches, dents, or bubbles

Mechanical Properties: Meets forming requirements without brittle fracture

Corrosion Resistance: Verified through salt spray testing