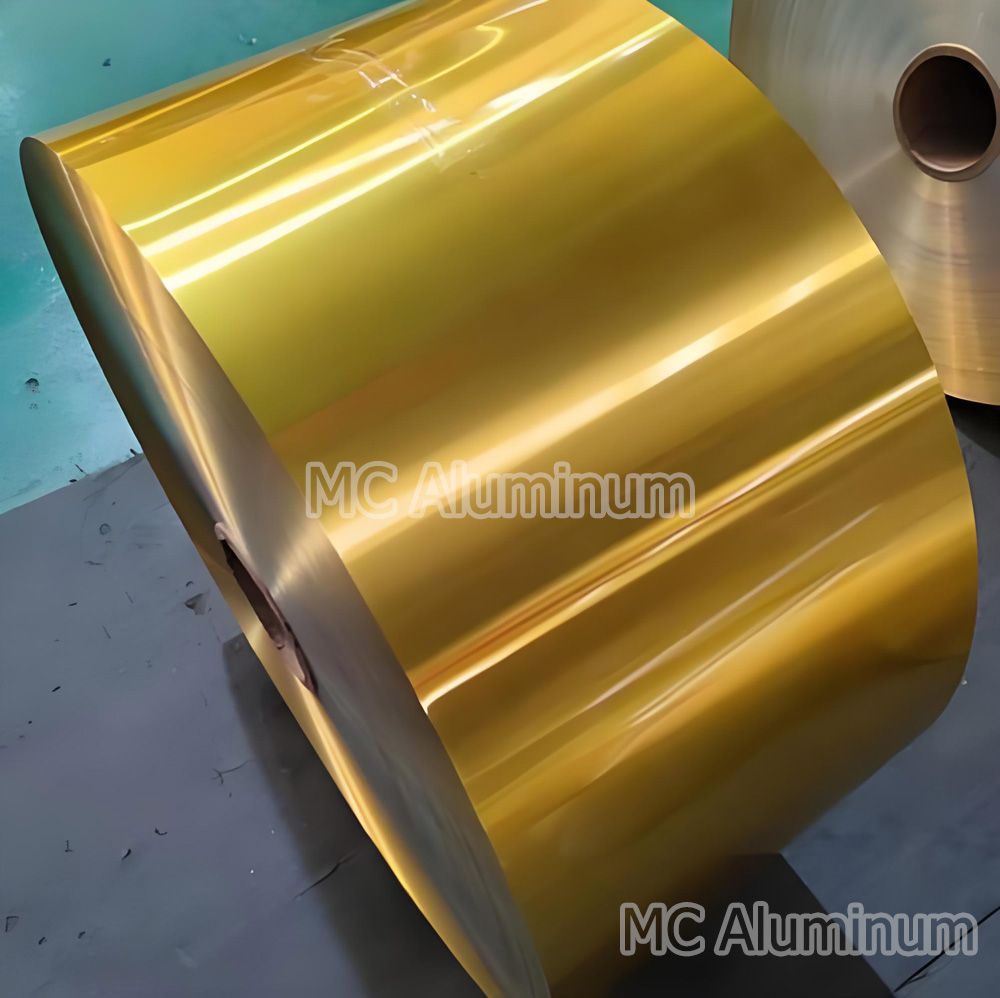

In modern manufacturing of air conditioning heat exchangers, evaporators, condensers, and other thermal exchange devices, material performance plays a decisive role in determining equipment stability and service life. 3102 hydrophobic epoxy coated aluminum foil roll, as a high-performance composite material, is widely used in HVAC systems, automotive thermal management, and cold chain equipment, thanks to its excellent thermal conductivity, corrosion resistance, and anti-contamination properties. It has become a preferred material for many manufacturers.

What is 3102 Hydrophobic Epoxy Coated Aluminum Foil?

3102 aluminum foil is a manganese-based aluminum alloy that offers good corrosion resistance and moderate strength. When a hydrophobic epoxy coating is applied through a specialized surface treatment process, it enhances the surface’s resistance to contamination and water adhesion while also improving corrosion resistance and surface protection.

Hydrophobic Epoxy Coating

Hydrophobicity, often referred to as the “lotus leaf effect,” means that the material surface repels water, preventing water from spreading out or sticking.

Coating Composition: Typically made of oil-modified epoxy resin, applied via advanced coating technology to give the foil extreme water repellency.

Performance: Water droplets form beads instead of spreading, allowing them to roll off easily—this helps prevent water accumulation and frosting on heat exchanger surfaces.

3102 Aluminum Foil Product Specifications

| Item | Specification |

| Alloy | 3102 |

| Temper | O, H22, H24, H26, etc. |

| Thickness | 0.05 mm – 0.2 mm |

| Width | 20 mm – 1500 mm |

| Length | 1000 mm – 6000 mm |

| Outer Diameter | 300 – 1200 mm |

| Inner Diameter | 75, 150, 200, 300, 400, 500 mm |

| Coating Thickness | 2 – 5 μm |

| Coating Type | Single/Double-sided hydrophobic epoxy |

| Coating Color | Transparent, black, blue (customizable) |

| Packaging | Roll with protective film, wooden case/pallet |

| Corrosion Resistance | ≥ 500 hours (Salt spray test) |

| Hydrophobic Angle | >90°, excellent water repellency |

| Adhesion Grade | Grade 0 (excellent) |

| Processing | Suitable for cutting, stamping, flanging, etc. |

| Corrosion Test | ASTM B117 ≥ 1000h = 10 |

| MOQ | 1–3 tons |

Performance Validation

| Test Item | Performance Data |

| Contact Angle | 152° ~ 164.9° |

| Coating Resistance | >10⁸ Ω·cm² (14 days in 3.5% NaCl) |

| Antibacterial Rate | >99% (against PAO1 strain) |

| Abrasion Resistance | Contact angle remains >150° after 500 cycles |

| Adhesion | Grade 0 (cross-cut test) |

Advantages of 3102 Hydrophobic Aluminum Foil

1. Outstanding Hydrophobicity

High contact angle ensures condensate water does not adhere, reducing frost and moisture buildup and improving heat exchange efficiency.

2. Excellent Corrosion Resistance

The epoxy coating forms a dense, chemical-resistant barrier that effectively blocks moisture, acids, and alkalis, thereby extending the equipment’s service life.

3. Environmentally Friendly & RoHS Compliant

Uses eco-friendly coating materials that comply with EU RoHS standards, making it suitable for export-oriented and energy-efficient appliances.

4. Excellent Formability & Process Adaptability

3102 alloy provides good ductility and formability, and the coating adheres strongly, withstanding complex shaping processes without peeling.

Typical Application Scenarios

Fins in residential and commercial air conditioner heat exchangers

Automotive evaporators and condensers

Cold chain logistics and refrigeration units

Fresh air systems and air purification devices

Heat dissipation components in photovoltaic inverters

Why Choose Us?

Equipped with advanced coated foil production lines and automated inspection systems

Provides one-stop aluminum foil customization and processing services

Complete technical support and after-sales service

Certified by ISO, SGS, and other international standards

Long-term partnerships with clients across HVAC, automotive, refrigeration, and electronics industries