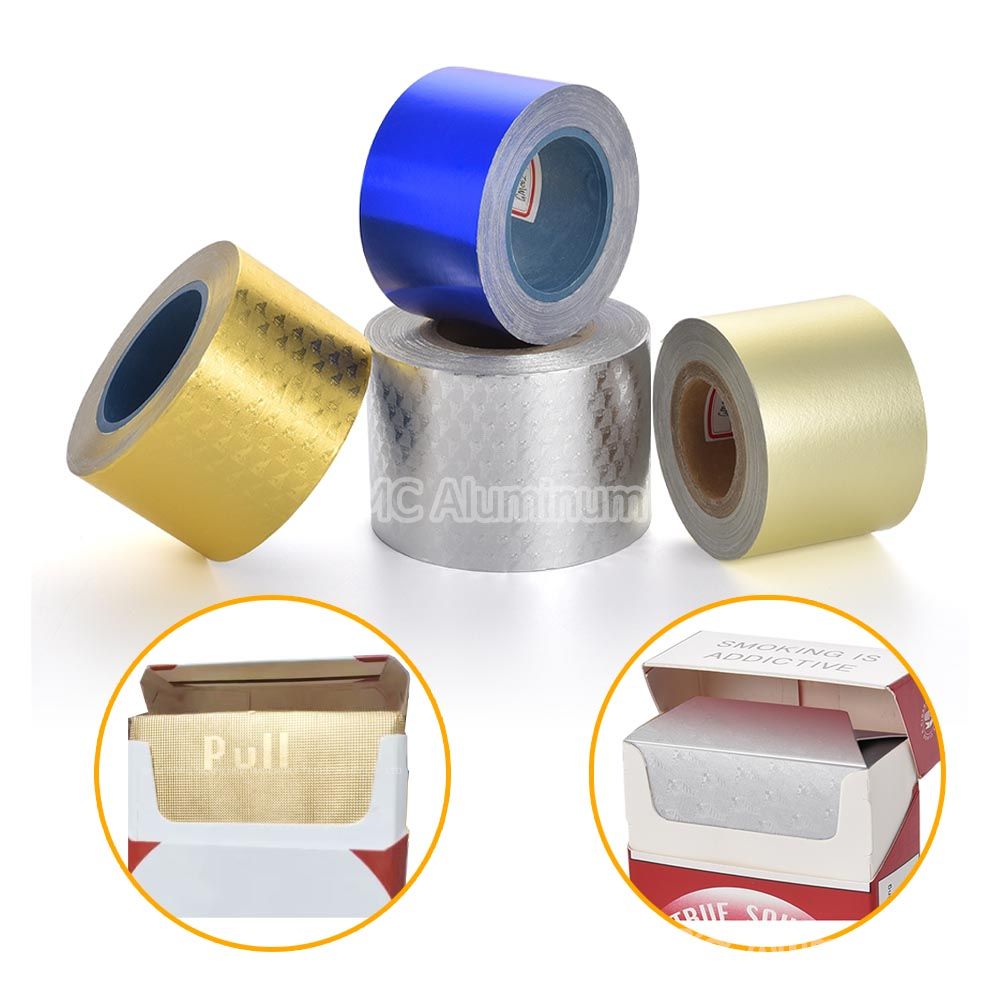

Gold and silver aluminum foil paper for cigarette packaging often referred to as cigarette inner liner foil is a premium composite material widely used in the tobacco industry. It is produced by laminating ultra-thin aluminum foil with backing paper, then finished with metallic gold or silver color to achieve a high-end appearance. Its primary role is to provide outstanding barrier protection that prevents aroma loss, blocks moisture, and enhances brand presentation through its luxurious metallic sheen.

This inner liner foil is typically manufactured using high-purity aluminum alloys such as 1235 and 8011, softened through O-temper annealing to ensure superior flexibility. It is then processed through coloring, embossing, and lamination to achieve the desired decorative and protective effects. The resulting foil exhibits excellent formability, tear resistance, and light-blocking performance, making it ideal for cigarette packaging lines.

Features of Gold and Silver Cigarette Inner Liner Foil Paper

High Barrier Properties: 100% barrier against light, oxygen, moisture, and odors, providing a reliable "sanctuary" for delicate tobacco and ensuring consistent taste before and after opening.

Flexible and Durable: Soft texture, easy to fold and wrap, while possessing sufficient stiffness and toughness to operate smoothly on high-speed packaging machines and withstand wear and tear from daily handling.

Safe and Environmentally Friendly: Aluminum foil itself is non-toxic and odorless, meeting food contact safety standards. Furthermore, aluminum is a recyclable material, aligning with modern green packaging concepts.

Product Specifications

| Alloy | 1235, 8079, 8011 |

| Temper | O / H18 (customizable) |

| Thickness | 0.0055-0.009 mm (typical: 0.006-0.0075 mm) |

| Width | 200-1600 mm |

| Length | 1000-16000mm |

| Color | Gold, silver, or customized |

| Surface Options | Bright, matte, embossed, color-coated |

| MOQ | 13 tons |

Technical Performance Indicators

| Moisture Barrier | ≤ 0.1 g/m²·24h |

| Color Tolerance | ΔE ≤ 1.0 within the same batch |

| Thickness Tolerance | ±4% (tighter tolerances available upon request) |

| Pinholes | Premium grade: 0-30 holes/m² |

| Standard grade: 0-100 holes/m² | |

| Tensile Strength (L/T) | 40-80 MPa depending on alloy and temper |

| Elongation | ≥10-30% (higher in O temper) |

| Water Vapor Transmission Rate | Almost zero (depending on composite structure) |

Key Performance Requirements for Cigarette Foil

1. High Barrier Properties

Foil must provide strong protection against moisture, oxygen, aroma loss, and light exposure.

2. Coating Adhesion

Color coatings must be durable, anti-powdering, and resistant to cracking suitable for high-speed packaging lines (300-500 pcs/min).

3. Flexibility & Formability

O-temper foil must fold sharply without rebound or breakage, ensuring precise inner-liner forming.

4. Roll Flatness

Foil must be smooth, wrinkle-free, and evenly tensioned for seamless machine processing.

5. Food Safety & Odor Control

The foil must comply with food-contact standards and be free from any unusual smell.

FAQ

Q1: Can gold and silver foil paper be customized in color?

A1: Yes. Options include bright gold, matte gold, rose gold, champagne, bright silver, matte silver, gradient colors, and custom shades.

Q2: Do you offer samples?

A2: Yes, samples of different thicknesses and surface finishes can be provided for testing.

Q3: What is the difference between gold and silver foil?

A3: The main difference lies in appearance and branding style.

Gold: more luxurious and premium

Silver: modern, clean, and high-tech look

Performance remains the same.

Q4: Is this foil suitable for high-speed cigarette packaging machines?

A4: Absolutely. The foil is engineered to resist tearing and maintain stable performance during high-speed folding.

Q5: What is the minimum order quantity (MOQ)?

A5: Generally 1-3 tons depending on thickness and surface treatment. Negotiable for export orders.