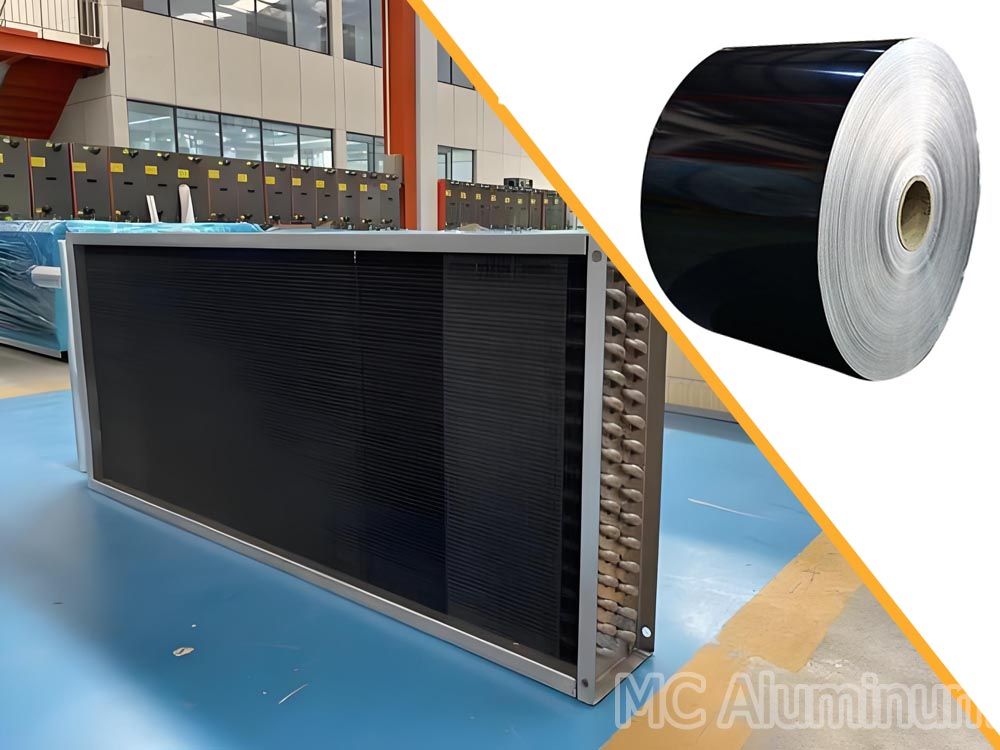

In the HVAC and home appliance industries, heat exchange efficiency and durability are core indicators of product quality. To meet the demand for high efficiency, low energy consumption, and long service life, MC Aluminum produces hydrophilic aluminum foil that fully meets these performance requirements. We offer blue-coated hydrophilic aluminum foil, gold hydrophilic foil, and black epoxy resin hydrophilic aluminum foil, widely used in industrial, electronics, aerospace, and other fields. The following article focuses on black epoxy resin hydrophilic aluminum foil.

What is Black Epoxy Resin Hydrophilic Aluminum Foil?

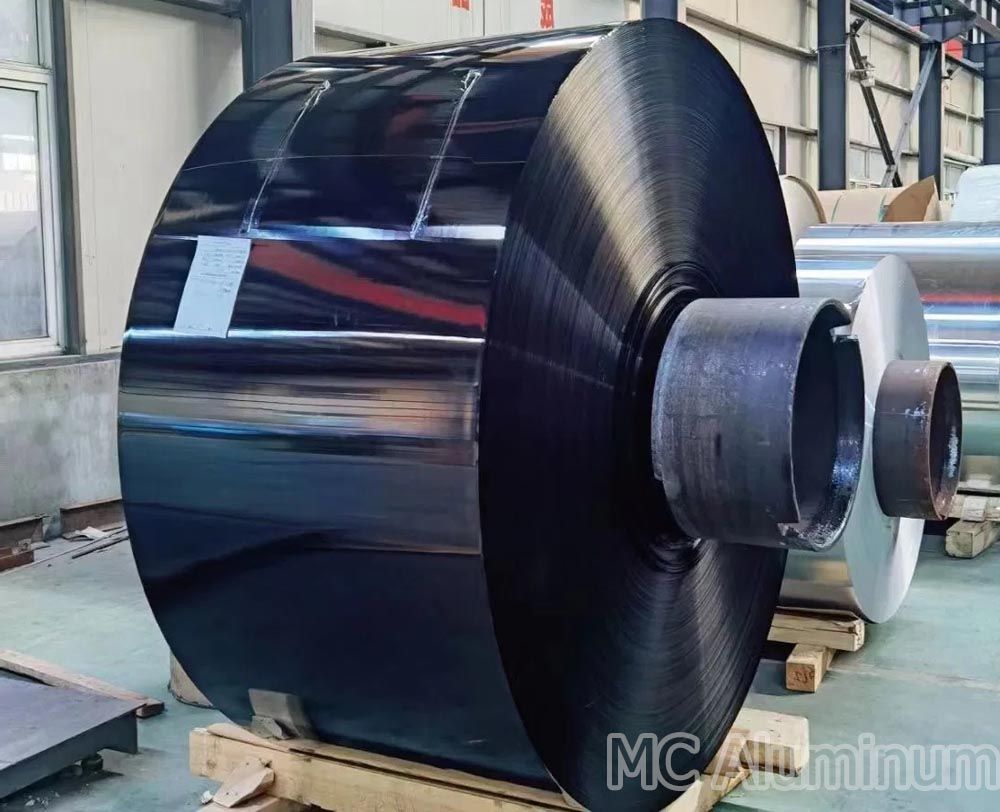

Black epoxy resin hydrophilic aluminum foil is made from aluminum foil (commonly 8011, 3102, 1100 alloys) as the substrate. A black epoxy resin hydrophilic coating is applied to the surface and cured at high temperature, resulting in a functional aluminum foil material. Its structure typically consists of three layers:

Aluminum Foil Substrate: Provides excellent thermal conductivity and structural support.

Black Epoxy Resin Layer: The core feature, giving the foil a sleek black appearance while providing strong corrosion protection.

Hydrophilic Coating: The outermost layer, designed to reduce water surface tension so that condensate spreads quickly and drains efficiently.

Material Properties

Function of the Black Epoxy Resin Layer:

(1) Corrosion Protection:

Forms a dense protective layer that resists refrigerants, humid environments, and airborne corrosive substances. Salt spray tests show 3-5 times longer corrosion resistance than standard aluminum foil, extending service life.

(2)Aesthetic and Functional Benefits:

Enhances infrared radiation for improved heat dissipation

Matches most home appliance designs, improving overall product quality

Resists fingerprints and water spots, maintaining a clean appearance

Function of the Hydrophilic Coating:

Ordinary aluminum foil has low surface energy, causing water to form discrete droplets (high contact angle). Hydrophilic aluminum foil increases surface energy via chemical treatment, allowing water to spread evenly into a thin film (contact angle <35°). Benefits include:

Improved heat exchange efficiency: Water film is much thinner than droplets, reducing airflow resistance by ~15-20%

Energy savings: Heat exchangers using hydrophilic aluminum foil can save 3–8% energy

Reduced "water bridge" effect: Prevents water droplet connection between fins, lowering airflow resistance

Technical Parameters

| Alloy | 8011 / 3102 / 1100, etc. |

| Temper | O / H22 / H24 / H26 |

| Thickness Range | 0.08-0.20 mm |

| Width Range | 200-1300 mm |

| Length | Customizable |

| Coating Type | Epoxy resin |

| Color | Black |

| Application | Air conditioners, refrigerators, and other cooling equipment |

| Features | Stable hydrophilic performance meeting process specifications, strong corrosion resistance; under neutral conditions (5% NaCl solution), 1500-hour testing achieves protection rating R.NO ≥9.8 |

| MOQ | 1-3 tons |

Core Advantages of Epoxy Resin Hydrophilic Aluminum Foil

1.Corrosion Resistance: The epoxy resin forms a dense cross-linked network that effectively isolates acid rain, salt spray, and industrial atmospheres from the aluminum foil.

2.Chemical Resistance: Resistant to acids, alkalis, and solvents.

3.Enhanced Heat Exchange Efficiency: The black epoxy hydrophilic coating allows condensate to form a continuous water film for smooth drainage, reducing airflow resistance and improving heat transfer efficiency.

4.Anti-Mold and Odor Control: Provides some antibacterial and anti-fungal properties, reducing mold growth and preventing odors during AC operation, improving indoor air quality.

5.Processability: The coating resists cracking or powdering during stamping, tube expansion, bending, and other processes, suitable for high-speed automated production, improving efficiency and yield.

6.Energy Saving and Environmental Benefits: Using hydrophilic aluminum foil can increase overall machine energy efficiency ratio (EER) by 0.1-0.3.

Production Process

1.Substrate Pretreatment: Aluminum foil is degreased, cleaned, and chemically converted to ensure surface cleanliness and improve coating adhesion.

2.Coating Preparation: Epoxy resin is precisely mixed with hydrophilic agents, black pigment, and auxiliary additives to form a uniform, stable coating solution.

3.Precision Coating: Roller or spray coating forms a uniform 5-15 μm thick layer on the aluminum foil surface.

4.Curing: The coating is baked for cross-linking; temperature and time are strictly controlled to achieve optimal performance.

5.Quality Inspection: Includes hydrophilicity testing (contact angle measurement), corrosion resistance testing, adhesion testing, and other procedures.

Applications of Hydrophilic Aluminum Foil

Home Appliances: Air conditioner heat exchangers, refrigerator condensers, dehumidifiers

Commercial & Industrial: Data center cooling systems, commercial refrigerated display cabinets, industrial refrigeration equipment