In the cigarette packaging industry, aluminum foil is required to meet extremely high performance standards, combining excellent barrier properties with good flexibility and processability. High-purity 1235 aluminum foil and high-strength 8011 aluminum foil stand out in packaging performance, printing adaptability, and environmental resilience, making them commonly used materials for soft cigarette inner liners.

1235 Aluminum Foil

This high-purity aluminum foil is renowned for its excellent ductility, processability, and smooth surface. It can be rolled to very thin thicknesses (typically 6-7 microns) while maintaining good strength and uniformity, providing a stable substrate for composite production. Its superior flexibility allows it to withstand complex folds and packaging processes of soft packs without cracking or forming pinholes, ensuring the integrity of the barrier performance.

8011 Aluminum Foil

As a commonly used alloy foil, 8011 contains small amounts of iron and silicon in addition to pure aluminum. This composition provides higher strength and better corrosion resistance than pure aluminum. In soft cigarette inner liners, 8011 aluminum foil offers additional mechanical strength, ensuring greater stability on high-speed packaging lines and reducing the risk of tearing or deformation. Its excellent formability also allows it to bond seamlessly with paper and other materials, forming a strong yet flexible inner liner.

Main Functions of Aluminum Foil in Soft Cigarette Packaging

1. Preserving Aroma and Flavor

The dense molecular structure of cigarette foil makes it an excellent barrier material, effectively preventing the loss of volatile aromatic compounds in tobacco and ensuring the distinctive flavor and aroma of cigarettes are retained.

2. Moisture and Mold Protection

Aluminum foil provides a highly effective moisture barrier, blocking the penetration of external humidity and air, preventing tobacco from becoming damp or moldy, and maintaining freshness while extending shelf life.

3. Flexibility and Deadfold Properties

For soft cigarette packs, the deadfold property of aluminum foil is crucial. This means the foil can retain its folded shape without springing back, allowing consumers to temporarily reseal opened packs, maintaining the freshness of the remaining cigarettes.

4. Oxygen Barrier and Light Protection

Aluminum foil prevents oxygen from entering the cigarette pack, slowing down the oxidation of tobacco. It also reflects and absorbs light, blocking UV radiation, which prevents the degradation of chemical components in tobacco and further preserves freshness.

5. Brand Presentation and Decoration

Aluminum foil has an elegant silvery sheen and can easily be embossed, colored, or printed with various designs, colors, and brand logos, enhancing the visual appeal of soft packs and imparting a premium feel.

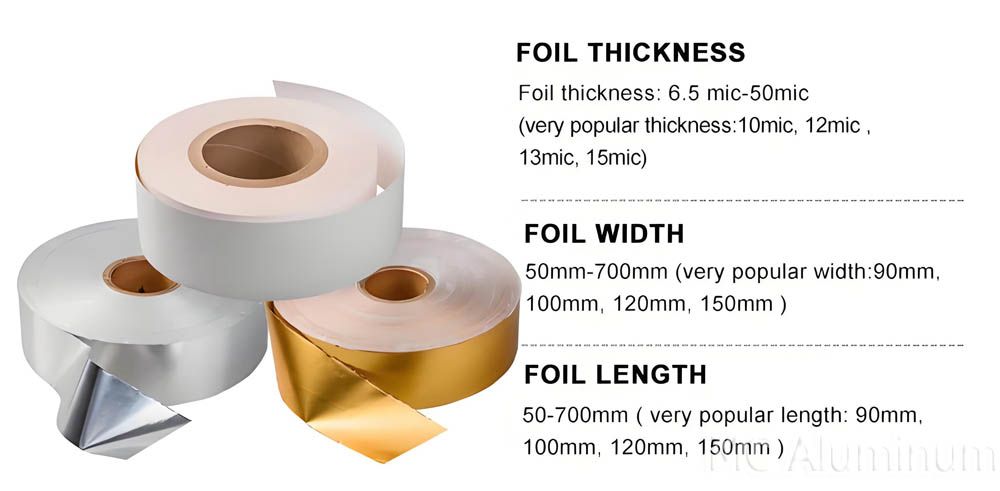

Specifications for Aluminum Foil in Cigarette Packaging

| Alloy | Temper | Size Specifications (mm) | |||

| Thickness | Width | Core inner diameter | Outer diameter | ||

| 1235,8011 | O | 0.0060~0.0090 | <1500.0 | 76.0,76.2 | 300~450 |

| 150.0,152.0,152.4 | 450~820 | ||||

| Thickness (mm) | Thickness tolerance (mm) |

| 0.0060~0.0065 | ±5%·T |

| >0.0065~0.009 | ±4%·T |

Number of pinholes

| Thickness (mm) | The number of pinholes is no more than 1/m. |

| 0.0060 | 1000 |

| >0.0060~0.0065 | 600 |

| >0.0065~0.0075 | 300 |

| >0.0075~0.0090 | 150 |

Appearance Quality Requirements

1. One side of the foil should be shiny and the other dull. The shiny side faces outward by default. If the dull side is required outward, this should be specified in the order or contract.

2. The foil surface must be clean and flat, free from insects, corrosion, roller marks, scratches, stains, dents, wrinkles, or noticeable color variations affecting usage.

3. Foil roll ends must be neat, with smooth edges free of burrs.

4. Rolls must be tightly wound, with no slippage between layers or detachment from the core.

Future Trends of Aluminum Foil in Soft Cigarette Packaging

Lightweighting: Optimizing foil thickness to reduce material use and transportation costs.

High-Barrier Multilayer Composites: Laminating with paper or plastic films to enhance barrier and moisture resistance.

Eco-Friendly and Recyclable: Increased use of recyclable materials in line with green packaging trends.

Smart Packaging: Exploring anti-counterfeit and traceable composite packaging solutions.

Premium Visual Effects: Incorporating hot stamping, embossing, and holographic effects to enhance brand recognition.