Hydrophilic Aluminum Foil in Modern HVAC Systems

In today’s HVAC (Heating, Ventilation, and Air Conditioning) systems, hydrophilic aluminum foil plays a crucial role, especially in the manufacture of heat exchanger fins such as evaporators and condensers. Through a specialized surface treatment, this foil significantly enhances system efficiency, durability, and user comfort.

What is Hydrophilic Aluminum Foil for HVAC?

Hydrophilic aluminum foil is an aluminum product coated with a water-based hydrophilic layer. It is primarily used in the heat exchange fins or radiators of HVAC units, air conditioners, ventilation equipment, and cooling systems. The hydrophilic coating offers excellent water-spreading properties, allowing condensation to form a thin, continuous film and drain smoothly. This prevents water droplet buildup, avoids blockage between fins, and improves heat exchange efficiency, reduces energy consumption, and extends system lifespan.

MC Aluminum provides hydrophilic aluminum foil in multiple alloy grades such as 8011, 1100, 3102, and 3003.Thickness range: 0.08–0.15 mm, with custom dimensions available.

Technical Specifications

| Alloy | 8011 / 1100 / 3102 / 3003 |

| Temper | O |

| Thickness | 0.08 mm – 0.2 mm |

| Width | 100 mm – 1300 mm |

| Length | 1000 mm – 16000 mm |

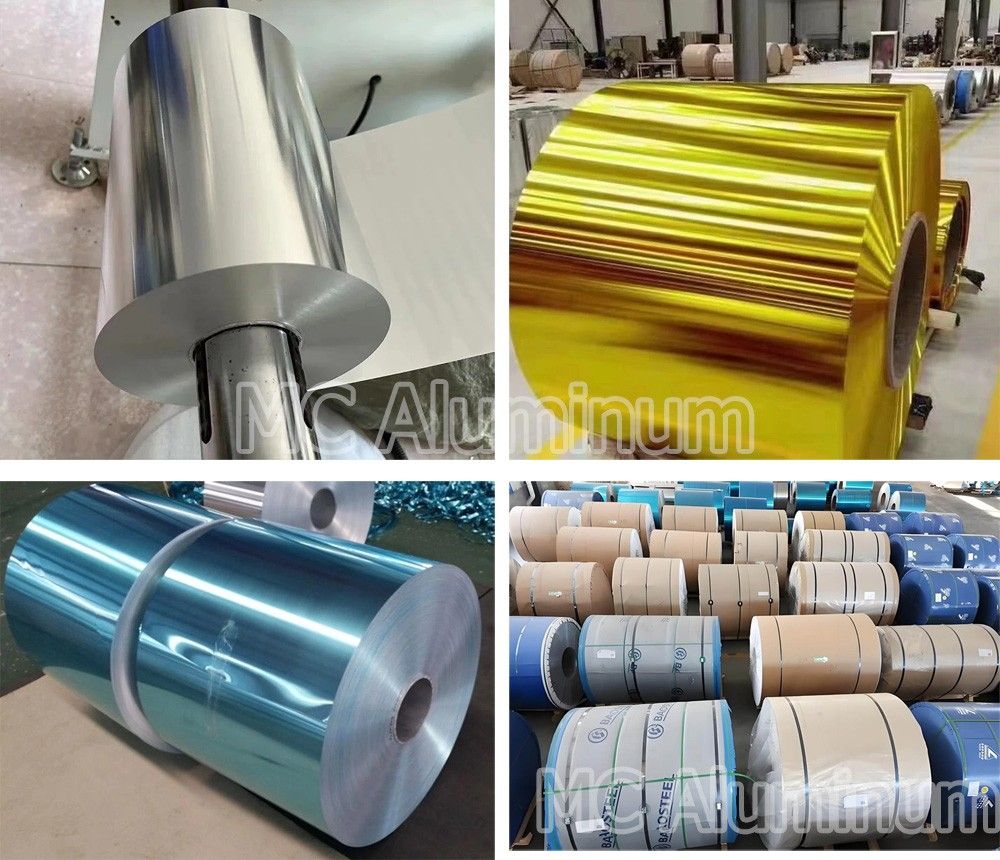

| Color Options | Blue, Gold, Green (customizable) |

| Coating Type | Water-based hydrophilic coating |

| Coating Thickness | 1.5 – 30 μm |

| Contact Angle (Hydrophilicity) | ≤10° |

| Salt Spray Resistance | ≥480 hours (no corrosion) |

| Adhesion (Cross Hatch Test) | Grade 0 (best rating) |

| Processing Method | Cold rolling + annealing + coating + curing |

Working Principle in HVAC Systems

Hydrophilic aluminum foil is mainly used in heat exchangers such as:

Evaporators (indoor unit in cooling mode):

Moisture in indoor air condenses on the cold evaporator fins. With standard aluminum foil, droplets form and may block airflow between fins. Hydrophilic foil enables water to spread as a film and flow away efficiently, maintaining airflow and boosting cooling efficiency.

Condensers (outdoor unit in heating mode):

Similarly, during heating or in outdoor units, hydrophilic foil aids in effective drainage of condensate, preserving optimal performance of the heat exchanger.

Core Advantages of Hydrophilic Aluminum Foil for HVAC

1. Superior Hydrophilicity for Smoother Drainage

The low surface tension of the coating allows condensation to spread and drain quickly, eliminating water bridges and improving airflow across fins.

2. Enhanced Heat Exchange Efficiency

By reducing surface water film thickness and increasing air velocity, heat exchange efficiency improves by 5%–15%, cutting down system energy consumption.

3. Excellent Corrosion Resistance

The coating often contains anti-corrosion additives that resist attack from refrigerants, humidity, and acidic/alkaline vapors, protecting the aluminum substrate from oxidation—especially effective in coastal or humid environments.

4. Outstanding Formability

The foil features excellent flexibility and coating uniformity, resistant to peeling or blistering. It supports deep drawing, continuous stamping, and fin-forming processes without quality loss.

5. Reduced Noise Levels

By preventing droplet vibration between fins, hydrophilic foil helps lower operating noise, enhancing user comfort.

6.Aesthetic Customization

In addition to the conventional blue coating, MC Aluminum offers hydrophilic foils in gold, green, and custom colors to enhance product identity and brand differentiation.

Application Areas of Blue/Gold Hydrophilic Aluminum Foil

Household Air Conditioners

As the primary material for air conditioning heat exchanger fins, hydrophilic foil plays a vital role in unit performance. It improves cooling efficiency by up to 5%, offers anti-corrosion and anti-mold protection, and prevents odor or condensate blockage issues.

Other Cooling Equipment

Widely applied in refrigerators, automotive air conditioning systems, dehumidifiers, and commercial ventilation units.

Comparison: Hydrophilic Foil vs. Ordinary Aluminum Foil

| Property | Ordinary Aluminum Foil | Hydrophilic Aluminum Foil (HVAC Grade) |

| Surface Treatment | None / Anodized | Hydrophilic & Anti-corrosion Coating |

| Drainage Performance | Poor – Water Accumulates | Excellent – Water Film Drains Smoothly |

| Heat Exchange Efficiency | Moderate | High |

| Service Life | Medium | Long – Salt Mist & Moisture Resistant |

| Formability | Average | Excellent |

| Maintenance Needs | Frequent | Low |

| Recommended Environment | Inland / Low Humidity | Coastal / High Humidity / Corrosive Zones |

MC Aluminum – Customization & Service Support

Custom thickness, coating types, and color options available

Services include slitting, rewinding, flattening, and protective film application

OEM and project partnerships supported

Sample testing and performance reports available

Compliance with RoHS, REACH, ISO 9001 quality systems

Bilingual technical documentation and export-ready marine packaging