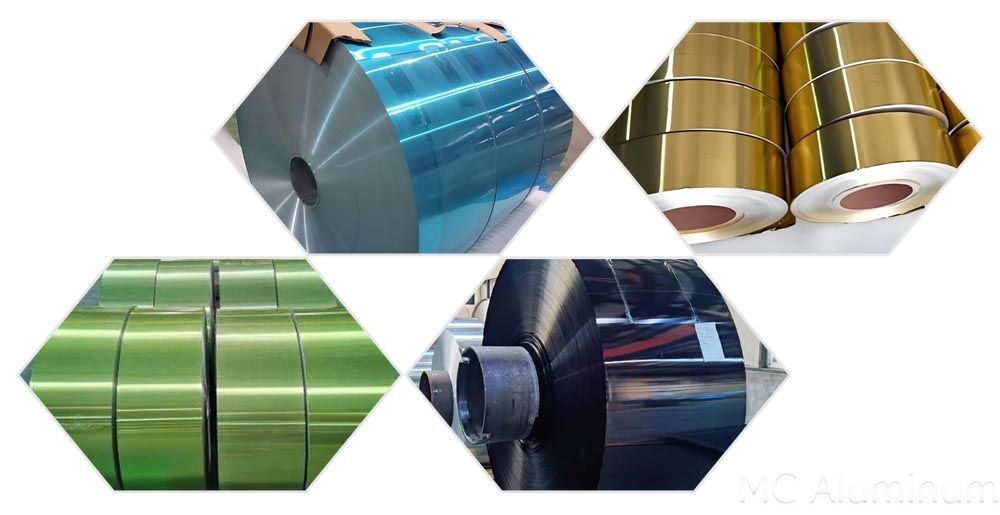

In the manufacturing of air conditioners, HVAC systems, and various heat exchangers, hydrophilic coated aluminum foil has become the mainstream material for evaporator and condenser fins. Observant users may notice that hydrophilic aluminum foil on the market is available in multiple surface colors,such as blue, gold, green, and even near-natural aluminum color-rather than just one standard appearance.

What Is Hydrophilic Aluminum Foil?

Hydrophilic aluminum foil is aluminum foil that has undergone special surface treatment. It is typically produced from aluminum alloys such as 1100, 3102, or 8011, with a common thickness of around 0.1 mm. It is mainly used in fins for air-conditioner condensers and evaporators, as well as frost-free refrigerator evaporators and other heat-exchange equipment.

Core Functions of Hydrophilic Coatings

Anti-bridging (prevention of condensate blockage):

Allows condensed water to spread quickly across the fin surface and flow downward as a continuous film, preventing water droplets from bridging between fins and obstructing airflow.Corrosion resistance:

Protects aluminum foil from atmospheric corrosion caused by salt spray, acid rain, and pollutants.Mold and odor resistance:

Reduces bacterial growth during air-conditioner operation, improving air quality.

Surface Color Options of Hydrophilic Aluminum Foil

The most common colors of hydrophilic aluminum foil on the market include blue, gold, green, and black. These colors are not randomly chosen; they are a direct result of differences in coating formulations and functional additives.

Blue Hydrophilic Coated Aluminum Foil

Blue is the most widely used and technically mature color in the air-conditioning industry. Blue hydrophilic coatings are typically based on water-based acrylic systems and may contain silver or copper ions to inhibit bacterial growth, making them suitable for hygiene-sensitive applications.

Visually, blue conveys a sense of stability and professionalism and is commonly used in industrial equipment and mid- to high-end HVAC products.

Golden Hydrophilic Coated Aluminum Foil

The distinguishing feature of golden coatings often lies in their enhanced anti-mold and antibacterial performance. In high-end applications or special environments, such as regions with high humidity, golden hydrophilic aluminum foil demonstrates better long-term stability.

The color itself may originate from specific antifungal agents or stabilizers incorporated into the coating formulation.

Green Hydrophilic Aluminum Foil

Green coatings are usually the result of deliberately added eco-friendly pigments or specific functional additives, such as chromium-free corrosion inhibitors. Green often serves as a visual identifier, indicating compliance with higher environmental standards or use in designated production lines requiring color differentiation.

In some cases, green coatings are also associated with added anti-mold and antibacterial functions.

Black Hydrophilic Aluminum Foil

Black hydrophilic aluminum foil typically indicates a coating system dominated by epoxy resin. Epoxy coatings are known for their excellent adhesion and superior chemical resistance, making black hydrophilic foil a professional solution for harsh environments.

Typical applications include air-conditioning systems used in coastal areas, industrial zones, or acidic operating conditions.

Comparison of Hydrophilic Aluminum Foil by Color

| Feature | Blue Hydrophilic Foil | Golden Hydrophilic Foil | Green Hydrophilic Foil | Black Hydrophilic Foil |

| Common Coating System | Water-based acrylic resin | Epoxy resin / organic-inorganic composite | Functional acrylic / composite system | Epoxy resin system |

| Core Functional Focus | Basic hydrophilicity, overall cost-performance | Durability, anti-mold & antibacterial | Environmental compliance, specific functions (e.g. chromium-free) | Outstanding chemical corrosion resistance |

| Hydrophilic Performance | Excellent (contact angle usually <10°) | Excellent with good long-term stability | Good, meeting standard requirements | Stable even in corrosive environments |

| Corrosion Resistance | Good (meets standard salt-spray tests) | Very good | Good (eco-oriented formulation) | Excellent (designed for acidic and high salt-spray conditions) |

| Typical Applications | Residential & commercial AC, standard environments | High-end appliances, high-humidity environments | Eco-labeled products, dedicated production lines | AC systems in acidic, coastal, or industrial environments |

FAQ

Q1: Does color affect the mechanical properties of aluminum foil?

A: Generally, no. Color is determined by the coating, while strength and ductility depend on the aluminum substrate. However, good adhesion between the coating and the substrate is essential to prevent peeling.

Q2: Can colors be mixed or customized?

A: In principle, yes. However, professionally formulated coatings are strongly recommended. Improper or self-mixed coatings may result in unstable performance, color inconsistency, or delamination.

Q3: How can coating color quality be evaluated?

A3:

Visual inspection: Check for uniform color and absence of defects.

Instrument testing: Use a colorimeter to measure color difference (ΔE); smaller values indicate better consistency.

Performance testing: Conduct water contact angle tests, abrasion resistance tests, and corrosion tests.

Q4: Does coating color affect the thermal conductivity of aluminum foil?

A: The impact is generally minimal. However, darker coatings (such as black) absorb more heat and may cause localized temperature rise, while lighter or transparent coatings reflect heat more effectively.