In air-conditioning heat exchangers (aluminum fins), the surface coating of aluminum foil directly affects heat transfer efficiency, drainage performance, corrosion resistance, and service life of the unit.

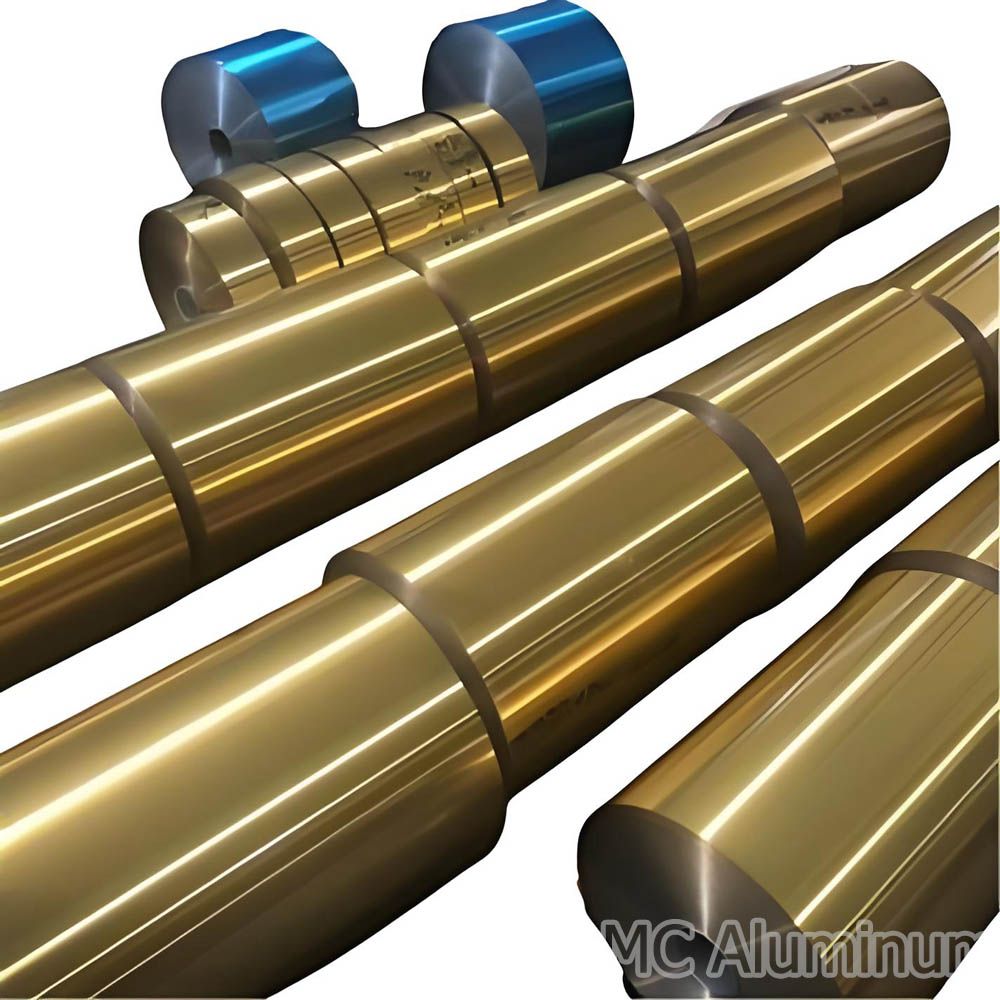

Currently, the two widely used functional coated aluminum foils in the HVAC industry are hydrophobic aluminum foil and hydrophilic aluminum foil. Both are usually based on substrates such as 3102, 8011, and 1100 aluminum foil, but their surface coating properties differ significantly.

What Is Hydrophobic Aluminum Foil?

Hydrophobic aluminum foil is coated with a hydrophobic resin or hydrophobic epoxy layer, making water adhesion very low. Its contact angle is typically greater than 90°, causing condensation to form independent droplets. Under gravity or airflow, water droplets easily roll off inclined or vertical fins rather than spreading into a film.

What Is Hydrophilic Aluminum Foil?

Hydrophilic aluminum foilis coated with a special polymer-based hydrophilic coating. This coating contains hydrophilic groups that reduce the surface tension of water, allowing condensation to quickly spread into a thin film. The water film flows smoothly along the fins without blocking air passages.

The key indicator of performance is the contact angle the smaller the angle, the more hydrophilic the surface. High-quality products often have an initial contact angle of less than 10°.

Hydrophilic aluminum foils are usually based on 3102, 8011, or 1100 aluminum alloys, and coating colors can include blue, gold, or transparent hydrophilic.

Core Differences Between Hydrophobic and Hydrophilic Aluminum Foil

1. Contact Angle

Hydrophobic Aluminum Foil: Contact angle > 90°

Hydrophilic Aluminum Foil: Contact angle < 90°

2. Heat Transfer Efficiency

Hydrophilic Aluminum Foil: More efficient; thin water film enables continuous heat transfer, ideal for evaporators and condensers.

Hydrophobic Aluminum Foil: Better at staying dry; reduces airflow resistance and prevents fin contamination.

3. Corrosion Resistance

Hydrophilic Aluminum Foil: Strong protection. Hydrophilic coatings are often multifunctional, offering excellent corrosion and oxidation resistance. They protect the aluminum substrate from acidic substances, salt spray, and pollutants, greatly extending heat exchanger life and reducing maintenance and replacement costs.

Hydrophobic Aluminum Foil: Less corrosion-resistant. Ordinary aluminum relies on a weak oxide layer, which is prone to pitting and crevice corrosion in humid, coastal, or polluted areas. White powder (aluminum oxide) may appear on the fin surface, and severe cases can lead to perforation.

4. Manufacturing Process

Hydrophilic Film: Usually prepared via subcrystalline copolymerization.

Hydrophobic Film: Prepared using cross-linking polymerization or modification techniques.

5. Noise and Hygiene

Hydrophilic Aluminum Foil: Quiet and clean. Water flows as a smooth film, avoiding droplet impact noise and airflow blockage. Some coatings also have anti-mold or antibacterial properties, helping maintain fin cleanliness and indoor air quality.

Hydrophobic Aluminum Foil: Can generate noise and mold. Large droplets hitting fins may cause noise, and stagnant droplets create conditions for mold and bacteria growth.

6. Coating Types

Hydrophobic: Hydrophobic resin, hydrophobic epoxy coating

Hydrophilic: Hydrophilic coating systems (blue, gold, black, transparent)

7. Applications

Hydrophilic Aluminum Foil: Preferred by mainstream and high-end HVAC manufacturers. Widely used in split-type air conditioners, central AC systems, refrigerators, freezers, and other cooling equipment where efficiency and longevity are critical.

Hydrophobic Aluminum Foil (bare aluminum foil): Still in use due to lower cost, but mostly limited to low-end or older models where the working environment is dry and efficiency or lifespan requirements are low.

How to Choose the Right Aluminum Foil for Air-Conditioning Applications

Consider the following factors when selecting materials:

Operating Environment

Coastal or industrial areas: Hydrophobic aluminum foil

Normal indoor environment: Hydrophilic aluminum foil

Type of Heat Exchange System

Evaporators and condensers: Hydrophilic coated aluminum foil

Special heat exchangers or drying equipment: Hydrophobic aluminum foil

Cost and Performance Requirements

Hydrophilic aluminum foil: Lower cost, widely used

Hydrophobic aluminum foil: Focused on durability and corrosion resistance