8079 aluminum foil is a thin aluminum sheet made from high-purity aluminum through cold rolling, annealing, and surface treatment processes. It is renowned for its high aluminum content, excellent ductility, superior thermal conductivity, and strong processability, making it widely used in food packaging, pharmaceutical packaging, battery pouches, and electronic heat dissipation applications.

The high-purity aluminum ensures excellent oxidation and corrosion resistance, allowing 8079 aluminum foil to maintain stable physical properties in various environments.

Technical Specifications of 8079 Aluminum Foil

Thickness: Typically ranges from 0.005mm to 0.2mm, with food-grade foils commonly at 0.006mm.

Width: Customizable between 20mm and 2100mm, with cutting available to meet client requirements.

Temper: H14, H18, H24, H32, O, and other tempers are available to suit different processing needs.

Customization: MC Aluminum, as a professional aluminum foil manufacturer, can provide tailored solutions based on client specifications.

Performance Features of 8079 Aluminum Foil

1. High Moisture Resistance: Effectively blocks external moisture, protecting the contents-ideal for food and pharmaceutical packaging.

2. Excellent Gas Barrier: Prevents oxygen and other gases from entering, prolonging product shelf life.

3. Elegant Silver Gloss: Enhances product appearance and market appeal.

4. Processability: Suitable for deep drawing, rolling, lamination, printing, and film coating, meeting diverse packaging and industrial requirements.

5. Lightweight and Corrosion-Resistant: Aluminum foil is inherently lightweight and resistant to corrosion, adaptable to multiple environments.

6. Eco-Friendly and Recyclable: 100% recyclable, supporting green initiatives and reducing environmental costs.

7. Safety: Complies with international food safety standards; non-toxic, tasteless, and safe for direct food contact.

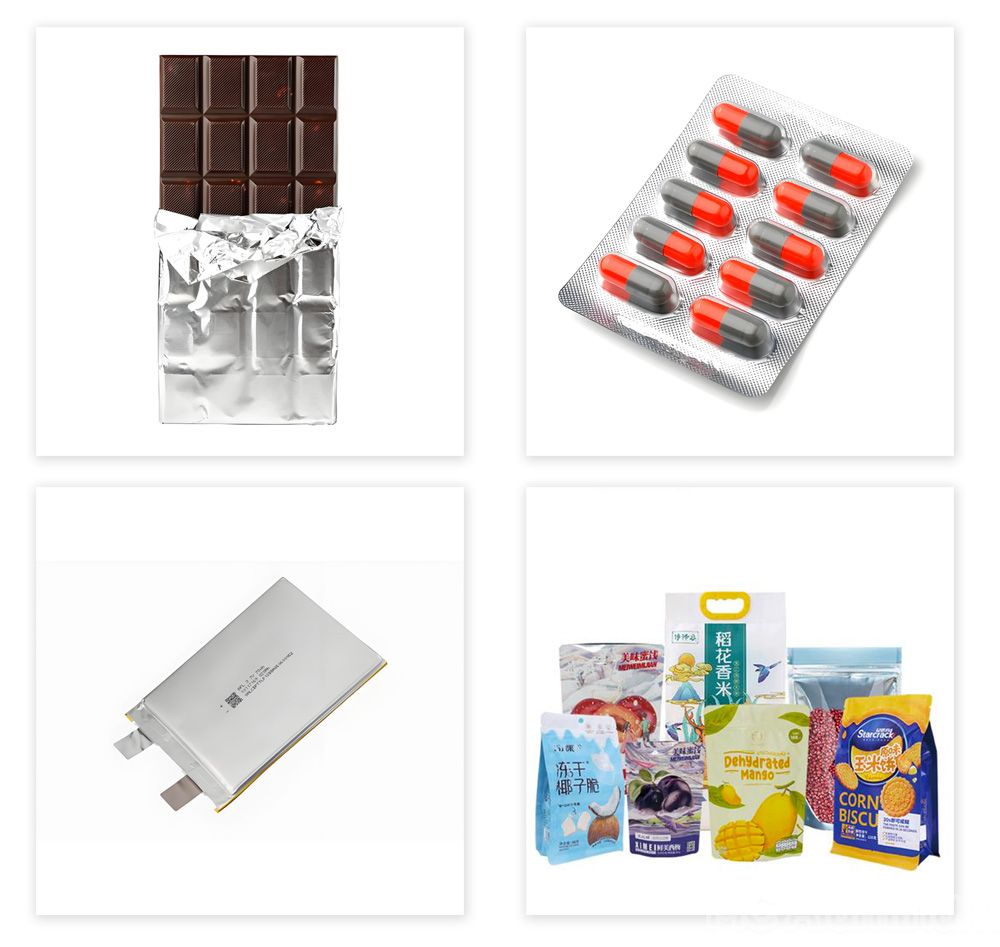

Applications of 8079 Aluminum Foil

1. Food Packaging

8079 aluminum foil can be used for packaging candies, chocolates, bread, mooncakes, and other food products. It not only provides excellent barrier properties and sealing but also ensures food freshness and hygiene.

2. Pharmaceutical Packaging

In pharmaceutical packaging, 8079 aluminum foil is used for tablets, capsules, ointments, and medical device packaging. Its high barrier properties and non-toxicity ensure that medicines are protected from moisture, oxygen, and light during transportation and storage.

3. Industrial Applications

8079 aluminum foil is widely used in the electronics, chemical, and machinery industries, such as in battery separators, thermal radiators, and industrial protective films, fully utilizing its high thermal conductivity, corrosion resistance, and flexibility.

4. Other Applications

8079 aluminum foil can also be used in coffee bags, tea packaging, cigarette packaging, ice cream packaging, and household kitchen aluminum foil, meeting various daily and industrial needs.

8079 Aluminum Foil Pricing

The price of 8079 aluminum foil is not fixed and depends on multiple factors:

Aluminum Ingot Price Fluctuations

8079 foil is made from high-purity aluminum, so domestic and international aluminum price changes directly affect ex-factory prices.

Thickness and Specifications

Variations in foil thickness, roll width, roll weight, and custom specifications affect production costs and pricing.

Processing Technology

Processes such as annealing, coating, printing, or lamination increase production costs.

Origin and Supply Chain

Manufacturer location, production capacity, and logistics costs influence final pricing.

Market Demand

Holidays, export orders, and peak seasons in food and pharmaceutical industries can temporarily increase prices.