In modern air conditioner manufacturing, aluminum foil heat exchanger fins are one of the core components, directly affecting the unit’s heat transfer efficiency, corrosion resistance, and appearance quality.

With technological advancements, 3102 aluminum alloy has become a mainstream material for producing AC fins due to its excellent thermal conductivity, corrosion resistance, and formability.

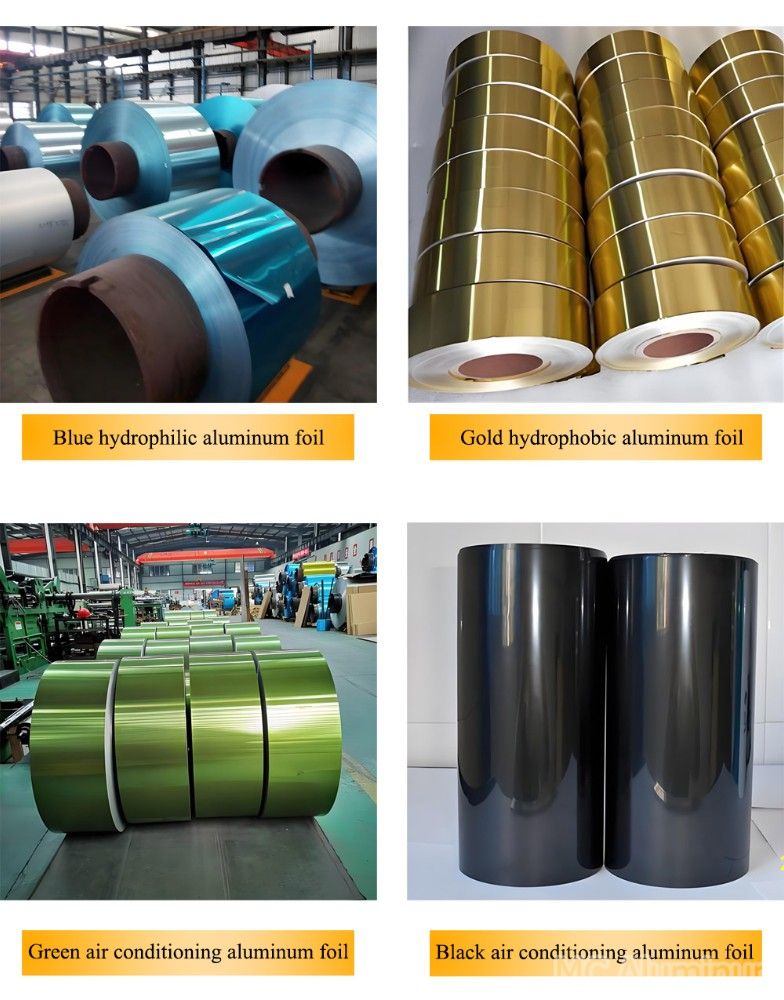

The base material of 3102 aluminum foil is silvery white. When used for air conditioning fins, it is usually coated with one or more functional layers, resulting in the common colors found in the market: blue, gold, green, and black.

Color Variants of 3102 AC Aluminum Foil

1. Blue Hydrophilic Aluminum Foil

Blue hydrophilic foil is the most common color for AC fins. During air conditioning operation, condensation forms on the evaporator fins. The hydrophilic coating allows the water film to spread evenly and flow off quickly, rather than forming droplets that fall.

Functions:

Improved Heat Transfer: The water film spreads uniformly, maintaining airflow and heat exchange efficiency.

Reduced Noise: Prevents dripping sounds caused by water droplets falling into the drip tray.

Basic Corrosion Protection: The coating offers a protective layer for the aluminum substrate.

2. Gold Hydrophobic Aluminum Foil

Gold coatings typically contain stronger anti-corrosion agents, effectively resisting humidity, acid rain, and salt spray, significantly extending fin lifespan. Some gold foils also include antibacterial agents. They usually have hydrophobic properties, allowing water droplets to slide off quickly, keeping the fins dry.

Functions:

Suitable for Harsh Environments: Ideal for coastal areas, high-humidity zones, or industrial pollution-heavy locations.

Mold Inhibition: Antibacterial properties reduce the chance of mold growth on fins.

3. Green Aluminum Foil

Green coatings usually include active antibacterial or antimicrobial agents. AC evaporators operate in a low-temperature, high-humidity environment, which is ideal for bacteria and mold growth.

Functions:

Effectively inhibits bacteria and mold on the fin surface, reducing internal contamination.

Helps maintain clean airflow output.

Applications:

Particularly suitable for areas with high air quality requirements, such as bedrooms, hospitals, or office environments.

4. Black Aluminum Foil

Black or dark-colored coatings provide higher corrosion resistance, excellent UV and oxidation protection, and are ideal for outdoor condenser applications.

Functions:

Some high-end "Black Diamond" coatings claim a self-cleaning effect, combining condensation water with a special chemical structure to wash the fins automatically.

MC Aluminum's air conditioning aluminum foil has been reduced in thickness from 0.15-0.2mm to 0.09-0.15mm, and coating technology has evolved from a single layer to a multi-layer composite structure. Colored aluminum foil not only improves performance but also facilitates quality traceability throughout the production process. Our products are exported to numerous countries, offering competitive prices and short delivery times, ensuring customers can place orders with confidence.