What is AC Aluminum Foil?

AC aluminum foil is a functional aluminum material specially designed for air conditioner heat exchangers such as evaporators, condensers, and duct-type exchangers. With thickness ranging from 0.08mm to 0.2mm, it is made from aluminum alloys like 8011, 1100, or 3102 through processes such as rolling, degreasing, coating, and baking.

Common Aluminum Alloys for AC Foil:

1100 Alloy: Known for excellent corrosion and heat resistance. Ideal for demanding HVAC applications.

1200 Alloy: Similar to 1100 but offers higher strength. Lightweight and corrosion-resistant.

3102 Alloy: Designed for high-end AC applications with higher density, suitable for advanced cooling systems.

8011 Alloy: Offers high strength and corrosion resistance. Common in both residential and commercial HVAC systems.

Types of AC Foil Based on Surface Treatment:

1. Hydrophilic Foil: Coated with a special hydrophilic layer for quick drainage and anti-condensation, improving heat exchange efficiency.

2. Hydrophobic Foil: Used in high-humidity or oily environments to prevent water accumulation.

3. Corrosion-resistant Foil: Coated to improve acid and alkali resistance, extending product lifespan.

4. Bare Foil: No surface coating; ideal for dry environments or internal structural use.

Product Specifications

| Alloys | 8011, 1100, 1200, 3102, 1030B |

| Tempers | O, H22, H24, H26 |

| Thickness | 0.08-0.2 mm |

| Width | 60-1440 mm |

| Length | 100-6000 mm |

| Outer Diameter | ≤ Φ1500 |

| Inner Diameter | Φ75 / 150 / 300 / 400 / 500 |

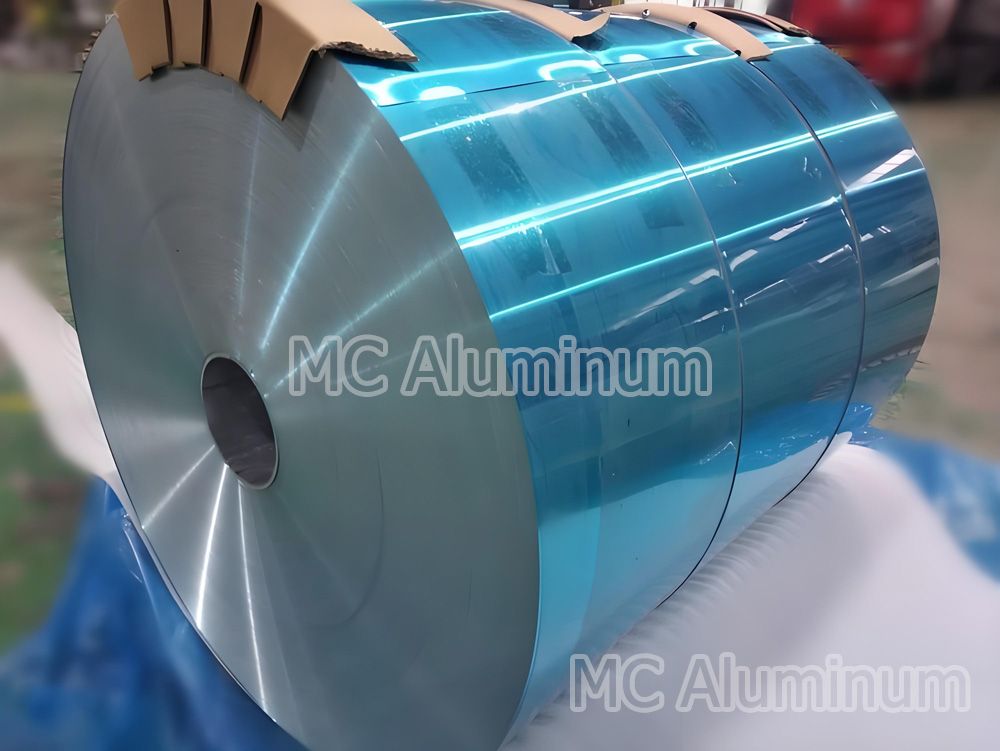

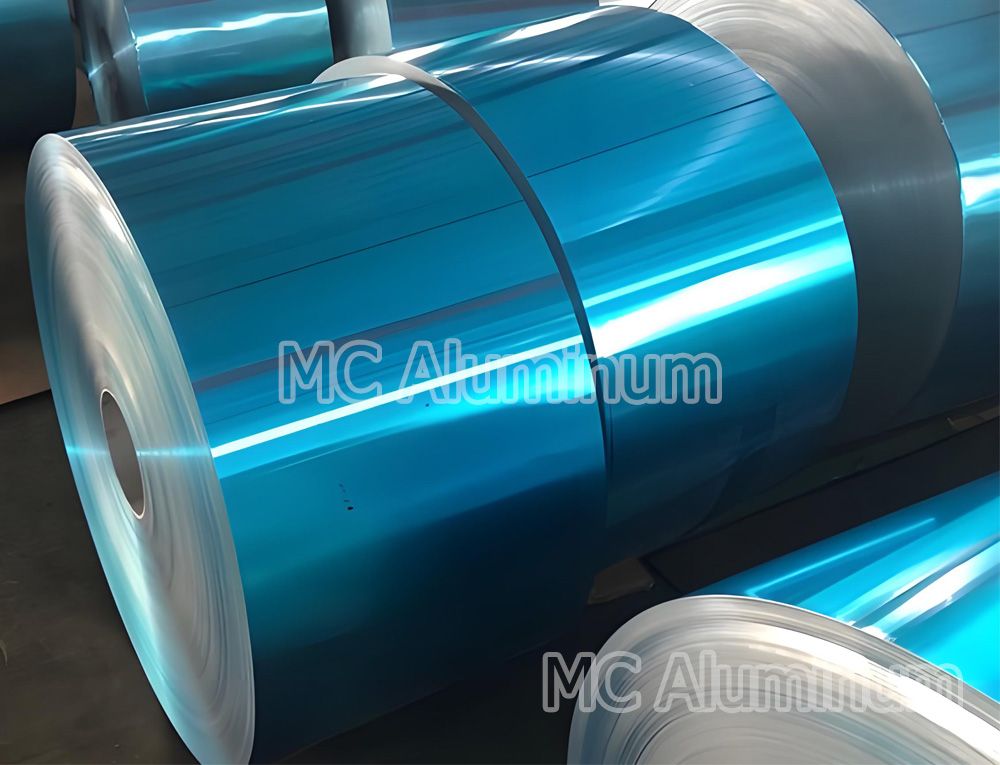

| Color | Blue, Gold |

| Applications | Widely used in air conditioners, coolers, evaporators, condensers, automotive and other heat exchange systems |

| Samples | Available |

| MOQ | 3 tons |

| Packaging | Wooden pallet or wooden box |

Hot-Selling AC Foil Products – MC Aluminum

Bare Aluminum Foil for Air Conditioners

Typically made from 1100 or 1200 series alloy and softened via O-temper annealing, bare foil provides excellent ductility and formability. As it has no surface coating, it's ideal for budget split AC units or coil insulation applications where corrosion resistance is not critical. Cost-effective and customizable via post-coating or lamination.

Hydrophilic Aluminum Foil for AC

The most widely used hydrophilic aluminum foil on the market, typically made from 8011 H24 alloy. Coated with a hydrophilic layer, it allows rapid dispersion of condensate, preventing frost and water buildup, keeping the heat exchanger surface clean and corrosion-free. Boosts cooling efficiency by approx. 5%, extends product life, and is widely used in residential, central, and automotive AC systems.

Hydrophobic Aluminum Foil for AC

This type of foil has a specially treated surface with a contact angle above 75°, effectively repelling water to prevent retention. Ideal for use in high-humidity environments such as underground facilities or coastal areas. Reduces mold risk and improves indoor air quality — a strong complement to conventional hydrophilic foil.

Coated Aluminum Foil for AC

Beyond hydrophilic and hydrophobic layers, aluminum foil for air conditioners may also use epoxy resin coatings or other anti-corrosion finishes. These improve acid, alkali, and oxidation resistance. Common colors include blue, gold, and green. Often used in export-grade or premium cooling systems.

Fin Materials – Aluminum Foil & Sheets

Thin-gauge aluminum foil or sheet is used as fin material in air conditioning systems. Common alloys include 1100, 1200, 8011, 8021, and 8079. Designed for large surface area and optimal thermal conductivity, fin foils significantly enhance heat dissipation - key to high-efficiency AC systems.

HVAC Aluminum Strips & Foil Ducts

Single-layer aluminum AC ducts are made from aluminum and polyester, providing flexibility and corrosion resistance. Easy to install and cut without special tools. Fire-rated and durable, ideal for HVAC duct connections.

Aluminum Foil Tapes for AC

Aluminum foil tapes for AC and refrigeration systems are coated with high-tack acrylic adhesive for excellent sealing, thermal insulation, and moisture resistance. Typical thickness: 18-25μm. Ideal for duct joints, seam sealing, and insulation layer fixation. Fire-resistant and thermally conductive versions available.

Aluminum Foil Insulation Tape for AC/Refrigerator Pipes

Specially designed for refrigerant pipe insulation in air conditioners, this tape features outstanding insulation and anti-corrosion performance. Helps reinforce pipes, reduce thermal loss, and maintain system stability.

Why Are Blue and Gold AC Aluminum Foils Most Common?

The color of AC aluminum foil is not just cosmetic — it directly affects performance and durability:

Blue Foil: Derived from acrylic hydrophilic coatings, blue foil enhances thermal efficiency. Widely used in standard home and commercial AC units.

Gold Foil: Features epoxy primer and metallic oxide pigmentation, enhancing salt spray resistance by up to 300%. Common in premium or custom products where higher corrosion resistance is required.

Performance Requirements for AC Aluminum Foil

Excellent Formability: Must withstand high-speed stamping for fin shaping without cracking.

High Strength & Uniformity: Ultra-thin foils need consistent thickness and flatness for structural stability.

Superior Thermal Conductivity: Crucial for efficient heat transfer.

Good Corrosion Resistance: Especially in humid environments, to ensure long service life.

High Cleanliness: Oil- and dust-free surfaces ensure proper coating adhesion and final performance.

Aluminum foil for air conditioners is the main product of MC Aluminum, and the main alloys that can be produced include 1030B-H26/3102-H26, 8011-O/8011-H22/8011-H24, 1100-H22, 8006-O/8006-H22, etc. Aluminum foil products are in good shape, with no pinholes, scratches, dents, oil stains, dust and other impurities on the surface, and uniform thickness.