PVC is a traditional shrink packaging material widely used to protect retail goods and food products. Upon heating, the film shrinks to tightly wrap around the product, offering comprehensive protection. It also serves a tamper-evident function for items requiring enhanced security.

For pharmaceutical protection, PVC rigid film offers excellent clarity, thermoformability, and barrier properties, effectively preserving the freshness of medications and protecting them from damage. Its transparent texture makes it easy to check the drugs in the package.

Features of PVC Film as a Packaging Material

PVC film offers the following characteristics that make it an effective and reliable packaging material:

Excellent thermoforming performance and dimensional stability

Minimal contamination risk to packaged items

Protection against moisture and gas penetration; resistant to chemical corrosion

Available in various colors, including transparent options

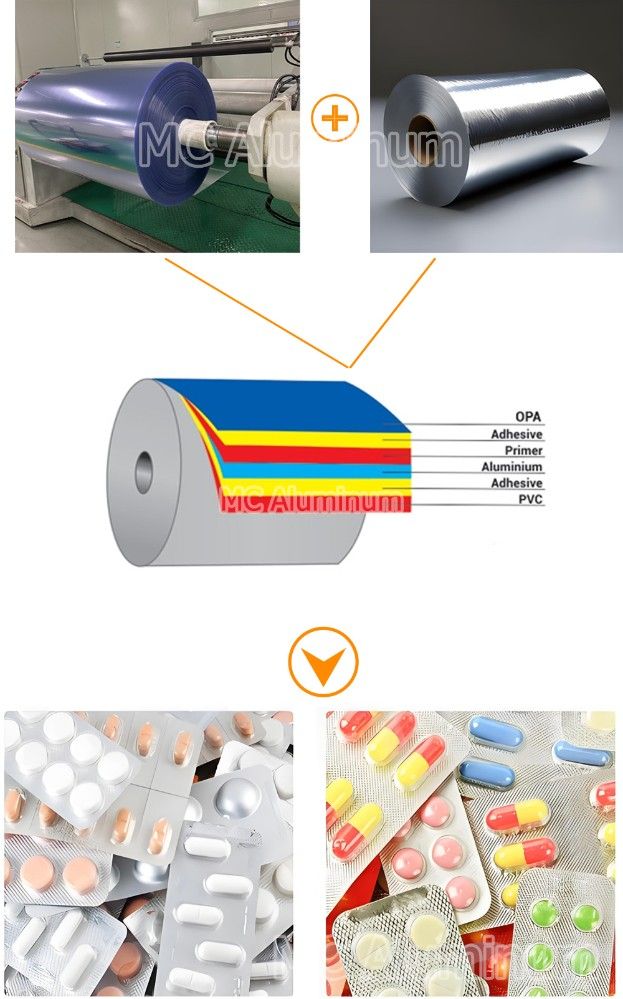

Composite Structures with PVC Film

| Material Structure | Function Description |

| PVC/PE | Enhanced heat-sealability, suitable for liquid drugs |

| PVC/PVDC | Improved barrier performance, moisture and oxidation resistance |

| PVC/OPA/ALU | High-barrier three-layer blister structure for premium drugs |

| PVC/ALU | General aluminum-plastic blister configuration |

Characteristics of PVC Film in Pharmaceutical Packaging

1.Transparency:

PVC film provides excellent optical clarity and surface finish, allowing clear display of the drug's appearance and condition.

2.Superior Formability:

With outstanding thermoplastic processing performance, it can be quickly thermoformed at lower temperatures, making it ideal for high-speed blister packaging lines. It maintains good dimensional stability after forming and can securely enclose medications of various sizes and shapes.

3.Cost-Effectiveness:

Compared to PET, PP, PVDC, and other pharmaceutical packaging materials, PVC film offers lower unit cost and broader supply availability. It is the preferred solution for pharmaceutical companies aiming to control packaging material costs and improve production efficiency.

4.Moisture and Chemical Resistance:

PVC film is highly resistant to moisture and chemicals. It is commonly used for packaging drugs that are sensitive to humidity or chemical exposure, helping to maintain drug stability and efficacy.

5.Easy to Sterilize:

To ensure safety and effectiveness, some medications must remain free from contamination or pathogens. Rigid PVC film is easy to sterilize, making it ideal for cleanroom environments and sterile product packaging.

6.Strength and Durability:

One of the main advantages of PVC film for pharmaceutical packaging is its strength and durability. It can withstand harsh handling and transportation conditions, ensuring that packaged products remain secure and intact during distribution.

Application Example of Rigid PVC Film

The most common application of PVC film in pharmaceutical packaging is blister packaging—used for tablets, capsules, and pills. In this format, PVC film acts as the forming base layer. It is thermoformed into individual “blisters” that securely hold each dose. These are typically sealed with a layer of aluminum foil serving as the lidding material.

MC Aluminum’s rigid PVC film contains no plasticizers and is calendered for pharmaceutical applications. It is available in a variety of thicknesses (maximum width: 640 mm; thickness: 0.10 mm – 0.50 mm; maximum outer diameter: 600 mm) and colors, making it highly suitable for the pharmaceutical industry.